BOILER

SEMAX OPTI

Essential Information

The SEMAX OPTI boiler is a boiler that gasifies pieces firewood in accordance with the 303-5:2021-09 standard. It is an ideal solution dedicated to people who have large stocks of properly stored firewood – hornbeam logs (logs) with a humidity of Wc=15-20%. . Operating our device at nominal power allows for better use of fuel and, as a result, cleaner exhaust gases emitted into the atmosphere. Additionally, the boiler is equipped with automation that regulates combustion and operation of the device. For proper operation of the entire system, the boiler must be connected to a buffer receiving excess heat.

Key benefits

Heat exchanger

Efficient design for quick cleaning of the exchanger from the front. The design of the boiler exchanger ensures high heat removal from the furnace.

Flue outlet

The structure of the boiler has been designed in such a way that the flue outlet is at the rear. The use of such a solution in a central heating boiler allows the flue to be directly led out to the chimney.

Exhaust gas temperature sensor

Exhaust fan

It is attached with an adapter to the rear vertical wall of the flue. The fan produces the necessary thrust needed for efficient fuel combustion.

Secondary and primary air intake

Smoke exhaust hatch

Baffle plates

Ceramic channel

Buffer tank

Accessories

Provides optimal working conditions for the boiler. The boiler can operate at optimal power, and the excess heat is stored in the buffer. The heating system of the house takes as much heat from the buffer as it needs at the moment.

ATTENTION!

Central heating boiler can only be installed in the heating system together with a buffer cylinder. The tank is not included in the price of the boiler.

Boiler control

The TECH ST-880 controller with PID is programmed to automate all processes related to home heating. Your role is only to enter the temperature you want in the room, and the controller will optimize combustion in this respect. Entering the advanced settings of the controller, you will be able to personalize many parameters related to combustion in the boiler, depending on your preferences!

Key features:

Standard equipment

Exhaust set which includes the TECH ST-880 controller with PID + exhaust fan. The controller also supports the buffer tank required to install the central heating boiler.

Optional equipment:

Manual firing up

Technical data of the boiler

| PARAMETERS | UNIT S.I. | SEMAX OPTI 16 |

| Nominal thermal power | [kW] | 16 |

| Boiler power range | [kW] | 16 |

| Heatable surface* | [m2] | 160-240 |

| Water capacity | [L] | 71 |

| Maximum working pressure | [bar] | 3 |

| Maximum working temperature | [°C] | 80 |

| Test pressure | [bar] | 4,5 |

| Glade circumference (tribe) | [cm] | 30-40 |

| Log length (strain) | [cm] | 26 |

| Fuel | [-] | firewood, pieces |

| Electrical connection | [-] | 1A; ~230V; 50Hz |

| Electric power consumption | [W] | 70 |

| Temperature controller setting range | [°C] | 60-80 (every 1°C) |

| Chimney draft required | [Pa] | 23 |

| Heat storage capacity (buffer) | [L] | 600 |

| Boiler weight | [kg] | 342 |

* A new building with very good thermal insulation was adopted for the calculations.

Certificates, class, boiler emission

| PARAMETERS | UNIT S.I. | SEMAX OPTI 16 |

| Ecodesign | [-] | Yes |

| Boiler class | [-] | 5 |

| Energy class | [-] | A+ |

| Seasonal particulate emissions | [mg/m3] | 20 |

| Efficiency for nominal power | [%] | 88,85 |

| Nominal emissivity of the particulate matter | [mg/m3] | 15 |

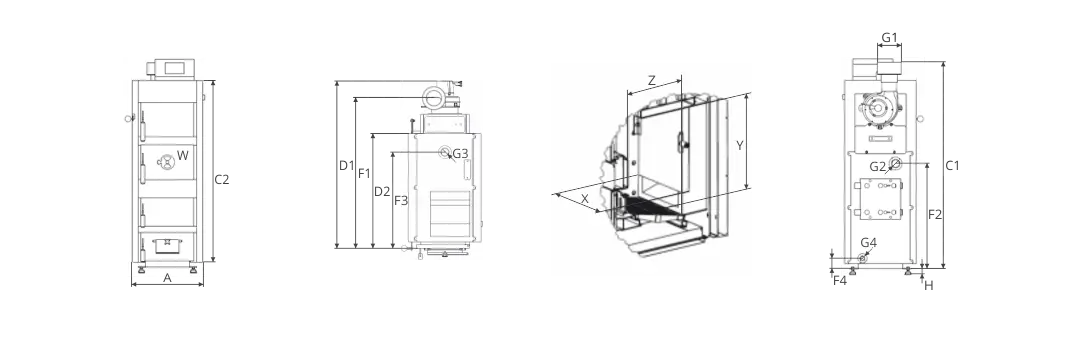

Boiler dimensions

| DIMENSION | UNIT S.I. | SEMAX OPTI 16 |

| A | [mm] | 490 |

| B1 | [mm] | – |

| B2 | [mm] | – |

| C1 | [mm] | 1380 |

| C2 | [mm] | 1260 |

| D1 | [mm] | 1070 |

| D2 | [mm] | 730 |

| E | [mm] | – |

| F1 | [mm] | – |

| F2 | [mm] | 713 |

| F3 | [mm] | 470 |

| F4 | [mm] | 82 |

| G1 | [mm] | 159 |

| G2 | [cal] | 1 1/2 |

| G3 | [cal] | 1 1/2 |

| G4 | [cal] | 3/4 |

| H | [mm] | 30 |

| W | [mm] | 290×200 |

| X | [mm] | 290 |

| Y | [mm] | 510 |

| Z | [mm] | 330 |

Boiler documentation

DTR instruction

| Technical and operational documentation | Download |

Driver manual

| ST-880 controller manual | Download |

EcoDesign certificate

| The boiler complies with the requirements of the EcoDesign standard (EkoProjekt) | Download |

Energy label

| A + energy class | Download |

Product sheet in accordance with EU regulation 2015/1187

| According to EU Regulation 2015/1187 supplementing Directive 2009/125 / EC of the European Parliament and of the Council | Download |

Product sheet in accordance with EU regulation 2015/1189

| Compliant with the EU Commission Regulation 2015/1189 of April 28, 2015 | Download |

Foreign sales

Paweł Czepiel

Export manager

Language: Russian, English

Monday-Friday (7:00 a.m. - 3:00 p.m.)

Phone:

+48 663 45 32 22

+48 85 711 94 54 ext. 17

E-mail:

p.czepiel@metalfach.com.pl

General contact:

Opening hours:

- Mon.-Fri. 7:00a.m.-3:00p.m.

- Phone: +48 85 711 94 54 int. 17

- E-mail: p.czepiel@metalfach.com.pl

General contact:

Service contact:

Opening hours:

- Mon.-Fri. 7:00a.m.–3:00 p.m.

- Phone: +48 85 711 94 54 int. 17

- E-mail: p.czepiel@metalfach.com.pl

Address data:

METAL-FACH Technika Grzewcza

Sp. z o.o.

- st. Sikorskiego 66, 16-100 Sokółka, Poland

- NIP: 545-182-60-12

- REGON: 523566030