SE MAX II

Available powers

15-50kW

Fuel

Guarantee

5 yearsextended*

General information

SE MAX II

15-50kW

Do you have a question about our offer?

Contact our representative.

User comfort

1. Miarkownik ciągu

2. Termometr mechaniczny

3. Kanały konwekcyjne

4. Wyjście czopucha

5. Czerpnia powietrza wtórnego

6. Dozownik powietrza

7. Duża komora załadunkowa

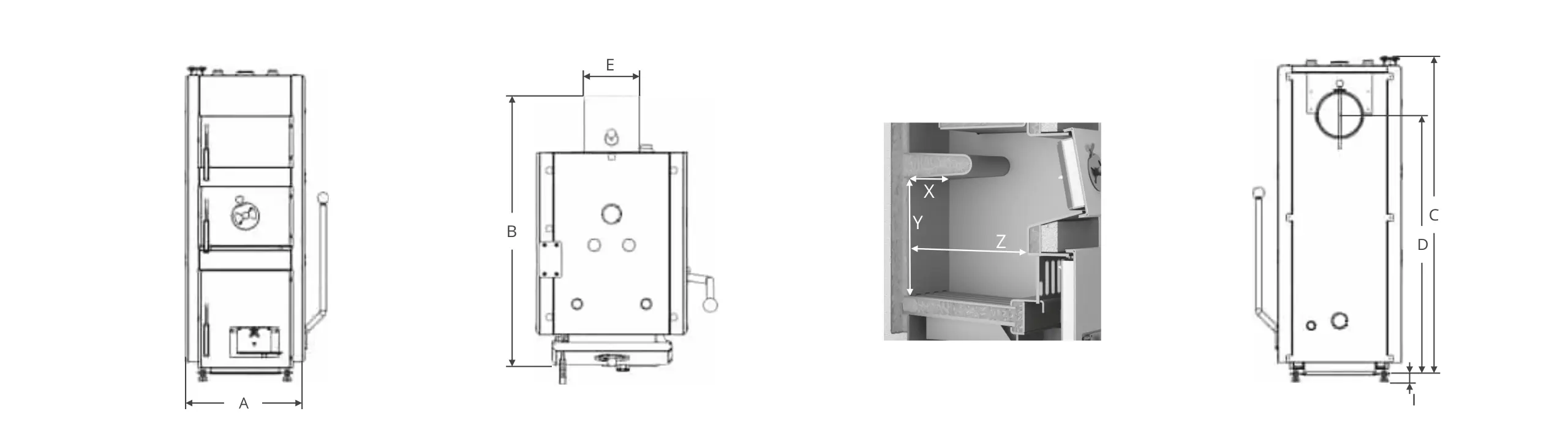

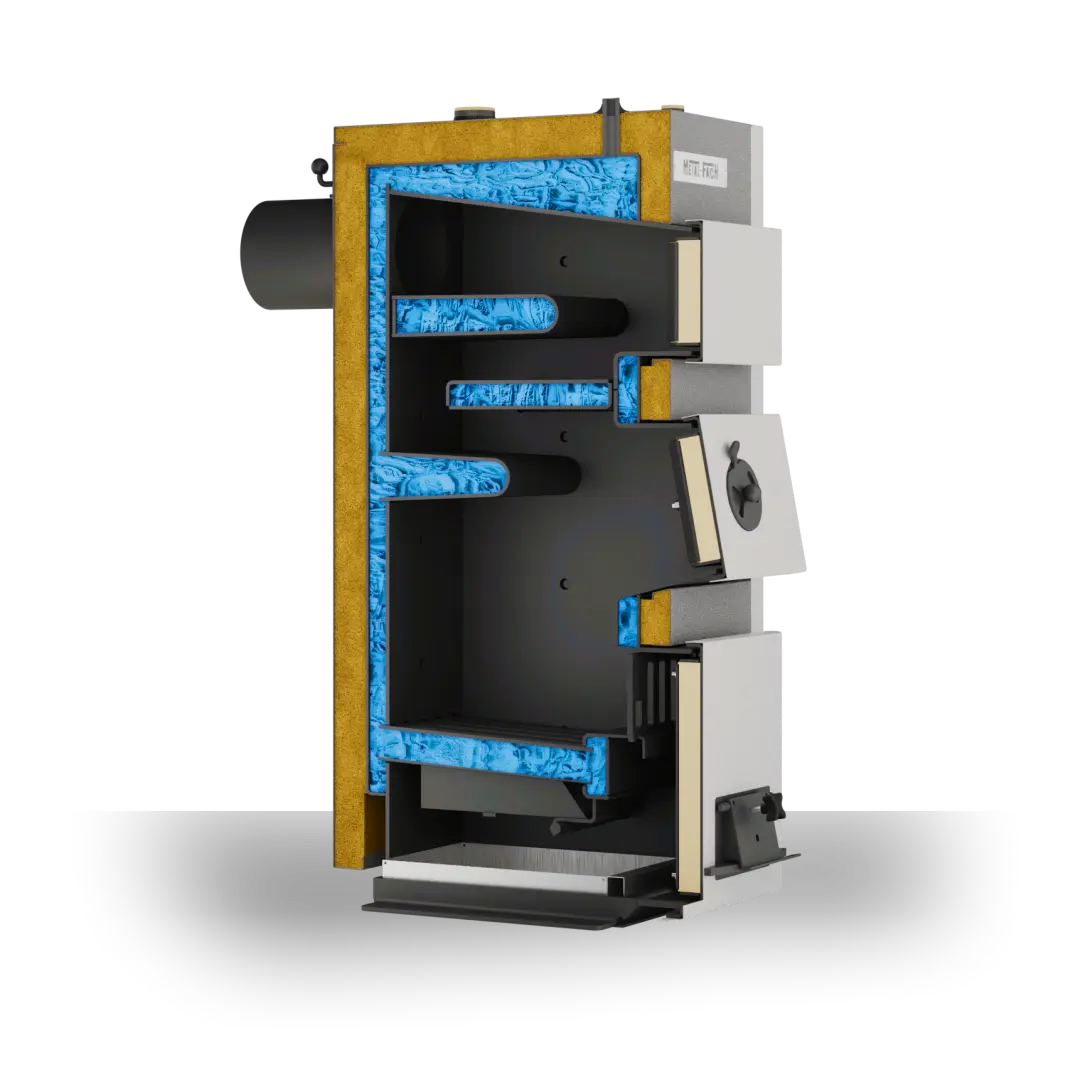

Construction of a central heating boiler

Draft regulator

Mechanical thermometer

Horizontal | shelf convection channels

Flue outlet at the back of the boiler

Secondary air intake

Air feeder

Large loading chamber

Any interference with the boiler’s design is prohibited and will void the warranty. Attempts to install additional grates or components that allow the combustion of fuels other than those specified by the manufacturer are prohibited.

Ecology and savings

Combustion chamber

- Easy and quick loading – a wide hopper makes it easy to refill wood and coal.

- Manual lighting – we can load firewood or coal into the combustion chamber. Wood, unlike coal, properly seasoned is an ecological fuel that meets all standards. It is fully natural, and as a result of combustion, biodegradable ash is created. By burning properly seasoned wood, we produce a small amount of harmful compounds into the atmosphere.

- Efficient combustion – thanks to the optimized supply of primary and secondary air, the fuel burns evenly.

- Long operation on one load – the refined large combustion chamber ensures optimal combustion conditions, which translates into longer boiler operation.

Controls

Accessories for central heating boilers

Equipmentadditional

DK SYSTEM-420 Controller

The DK SYSTEM-420 controller is a modern solution that automates part of the heating processes, ensuring comfort and efficiency in managing the temperature at home. The controller optimizes combustion in the boiler, adjusting its operation to the temperature set by the user. Thanks to this, the system ensures fuel savings, stability of the combustion process, constant water temperature in the heating system and greater thermal comfort in the rooms.

Draft regulator

The use of a draft regulator in a boiler is a key element in controlling the combustion process of wood or hard coal. This device allows for manual adjustment of the flap supplying air to the combustion chamber, maintaining the set temperature of the heating medium. Adjustment of the amount of secondary air is possible thanks to special slides. Simple, mechanical adjustment ensures easy adjustment of the boiler operation to the current thermal needs of the building and enables stable, effective and economical gasification of wood.

Exhaust fan

The use of an exhaust fan with adjustable height allows its output to be adjusted to the existing chimney installation, maintains appropriate draft, ensures even combustion and increases safety by preventing the backflow of exhaust gases.

Technical data

Parameters

Parameter

SE MAX II 15

SE MAX II 20

SE MAX II 20

SE MAX II 30

SE MAX II 35

SE MAX II 40

SE MAX II 50

Dimensions

Dimension

SE MAX II 15

SE MAX II 20

SE MAX II 25

SE MAX II 30

SE MAX II 35

SE MAX II 40

SE MAX II 50

Documentation

Contact with advisor

- Paweł Czepiel

- EExport Manager

- Region: Europe, World

- Language: English, Russian

- Mon-Fri 7:00-15:00

- +48 663 45 32 22

- +48 85 711 94 54 ext. 17

- p.czepiel@metalfach.com.pl

Our products

Pellet boilers

Wood gasification boilers

Wood boilers

Eco-pea coal boilers

Hydraulic clutches and central heating distributors

Agricultural machinery

Do you have a question about our offer?

Contact our representative.

Offer

Shopping and advice

Service and services

Contact

- METAL-FACH Technika Grzewcza Sp. z o.o.

- st. Sikorskiego 66, 16-100 Sokółka, Poland

- NIP: 545-182-60-12

- REGON: 523566030

- Mon-Fri 07:00-15:00

- Phone: +48 85 711 94 54

- sprzedaz@metalfach.com.pl

2026 © Copyright METAL-FACH Technika Grzewcza Sp. z o.o.