SEMAX BASIC

Available powers

15-40kW

Fuel

Energy class

A+

Guarantee

5 yearsextended*

General information

SEMAX BASIC

15-40kW

Do you have a question about our offer?

Contact our representative.

User comfort

2. Mechanical thermometer

3. Swirlers

4. Convection channels

5. Smoke outlet

6. Secondary air intake

7. Smoke extraction flap

7. Ceramic plates

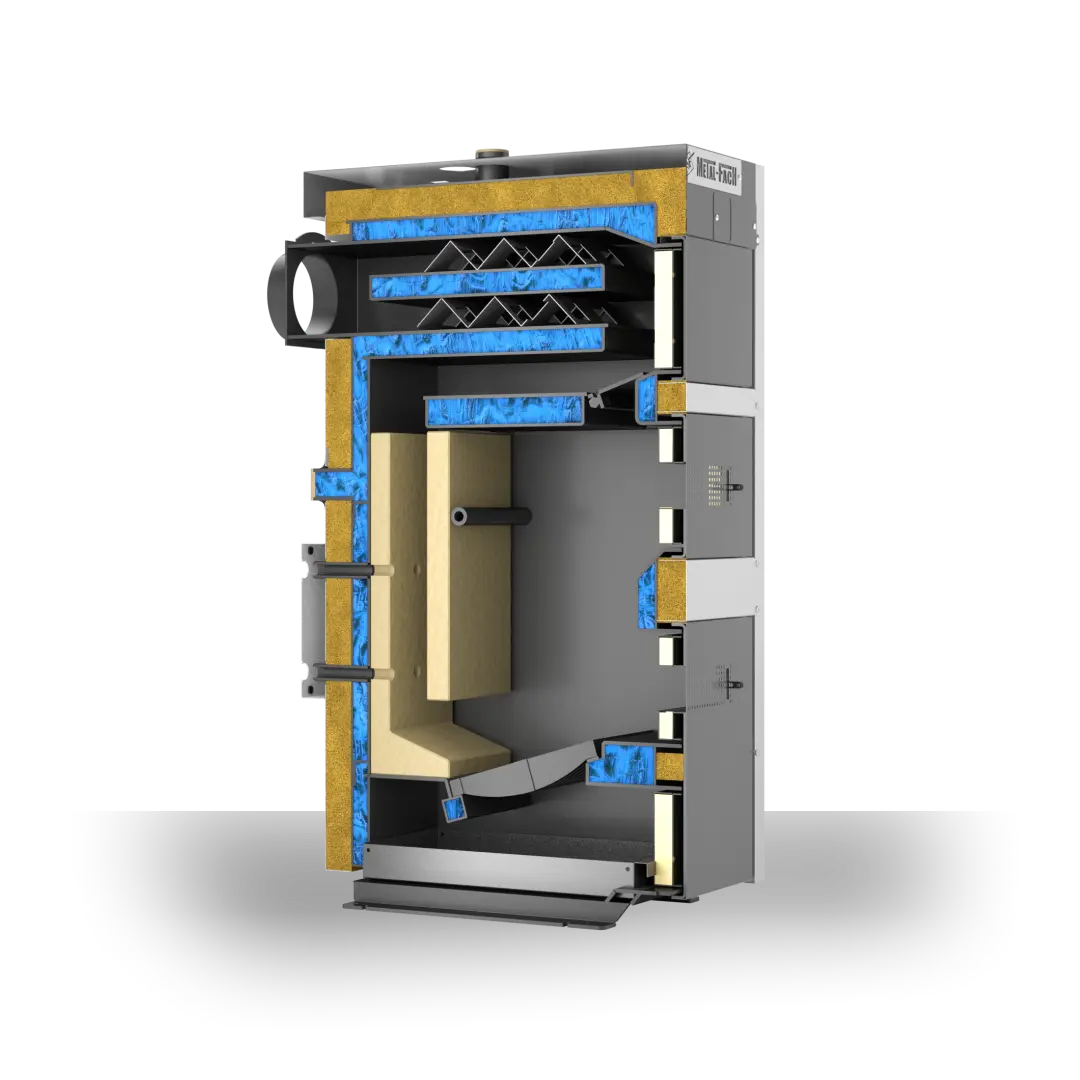

Construction of a central heating boiler

Draft regulator

Mechanical thermometer

Swirlers

- Increases heat exchange efficiency - swirlers cause turbulence in the exhaust gases, which improves heat transfer to the water jacket.

- Reduces fuel consumption - better heat exchange means lower energy losses and more economical operation of the boiler.

Horizontal convection channels | shelf

Flue outlet at the back of the boiler

The boiler design has been designed in such a way that the flue outlet is located at the back of the boiler. The use of such a solution allows for the flue outlet to be directly led out to the chimney.

Secondary and primary air intake

Air is drawn in through six holes to fully burn the fuel. The amount of secondary and primary air can be adjusted using sliders.

Smoke extraction flap

Ceramic plates

Buffer tank

(Additional equipment)

Ensures optimal operating conditions for the boiler. The boiler can operate at optimal power, and excess heat is stored in the buffer. The home heating system draws as much heat from the buffer as it needs at a given moment.

Note! The central heating boiler can be installed in the heating system only together with a buffer tank. The tank is not included in the price of the boiler.

Any interference with the boiler’s design is prohibited and will void the warranty. Attempts to install additional grates or components that allow the combustion of fuels other than those specified by the manufacturer are prohibited.

Ecology and savings

Gasification chamber

Controls

Controls

Thrust ruler

Technical data

Parameters

Parameter

SEMAX BASIC 15

SEMAX BASIC 20

SEMAX BASIC 30

SEMAX BASIC 40

Emissions / Efficiency

Parameter

SEMAX BASIC 15

SEMAX BASIC 20

SEMAX BASIC 30

SEMAX BASIC 40

Certificates

Parameter

SEMAX BASIC 15

SEMAX BASIC 20

SEMAX BASIC 30

SEMAX BASIC 40

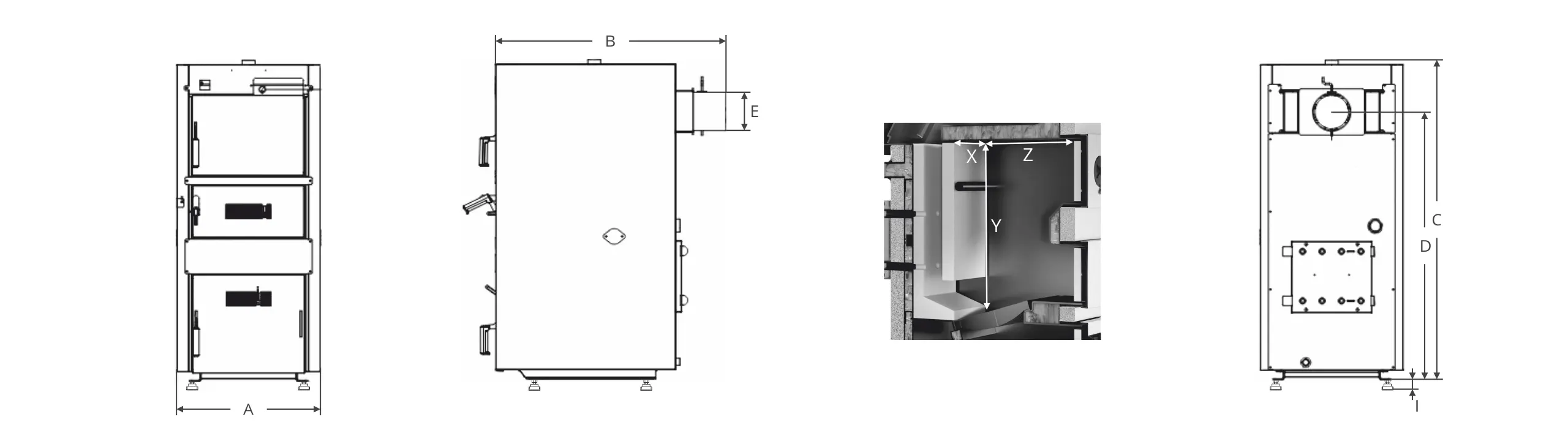

Dimensions

Dimension

SEMAX BASIC 15

SEMAX BASIC 20

SEMAX BASIC 30

SEMAX BASIC 40

Documentation

Certificate

Product card 2015/1187

Contact with advisor

- Paweł Czepiel

- EExport Manager

- Region: Europe, World

- Language: English, Russian

- Mon-Fri 7:00-15:00

- +48 663 45 32 22

- +48 85 711 94 54 ext. 17

- p.czepiel@metalfach.com.pl

Our products

Pellet boilers

Wood gasification boilers

Wood boilers

Eco-pea coal boilers

Hydraulic clutches and central heating distributors

Agricultural machinery

Do you have a question about our offer?

Contact our representative.

Offer

Shopping and advice

Service and services

Contact

- METAL-FACH Technika Grzewcza Sp. z o.o.

- st. Sikorskiego 66, 16-100 Sokółka, Poland

- NIP: 545-182-60-12

- REGON: 523566030

- Mon-Fri 07:00-15:00

- Phone: +48 85 711 94 54

- sprzedaz@metalfach.com.pl

2026 © Copyright METAL-FACH Technika Grzewcza Sp. z o.o.