SEG BIO

Available powers

15-75kW

Fuel

Pellet

Energy class

A+

Guarantee

5 yearsextended*

General information

SEG BIO

15-75kW

Do you have a question about our offer?

Contact our representative.

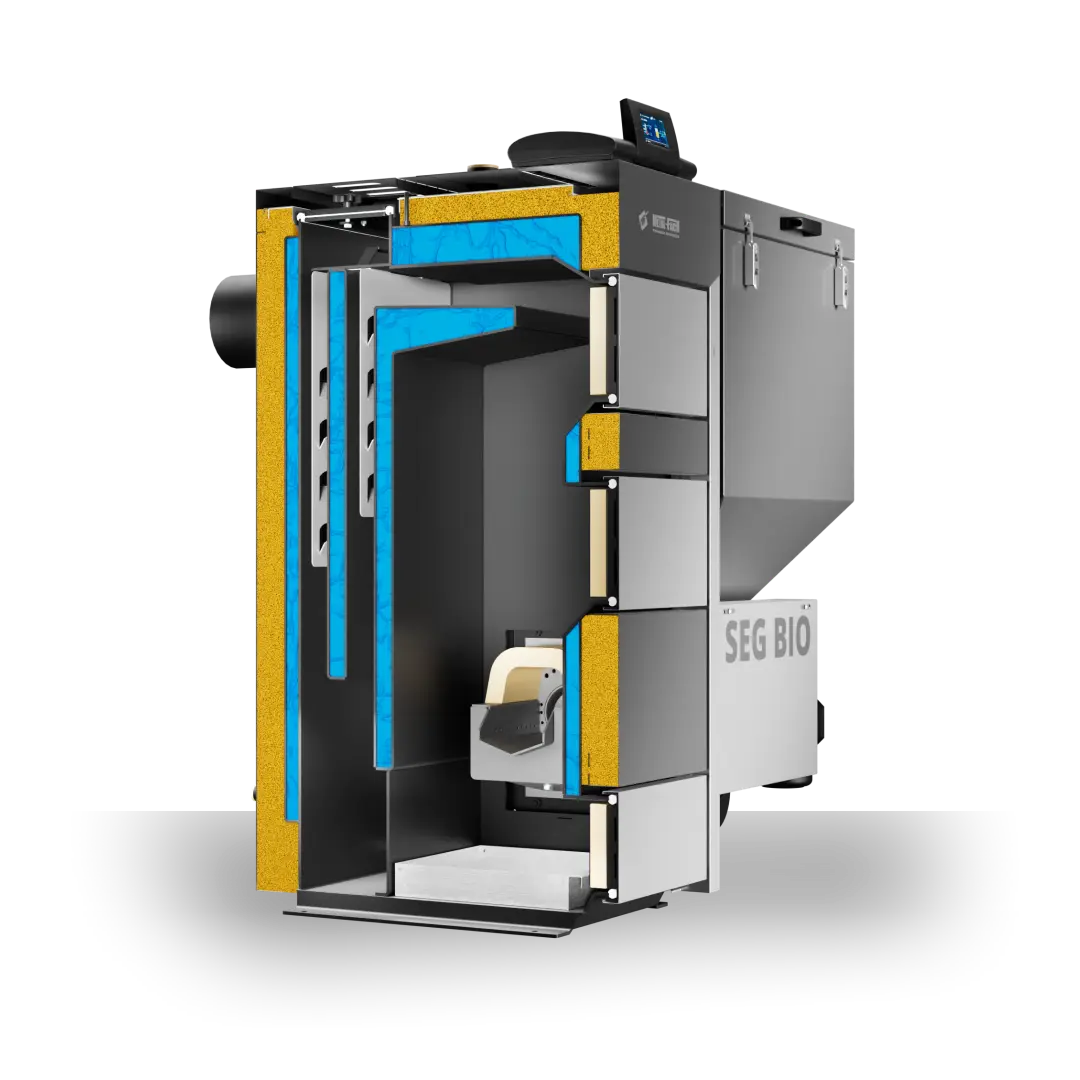

AR technology

User comfort

4. Vertical convection channels

(at the back of the tank)

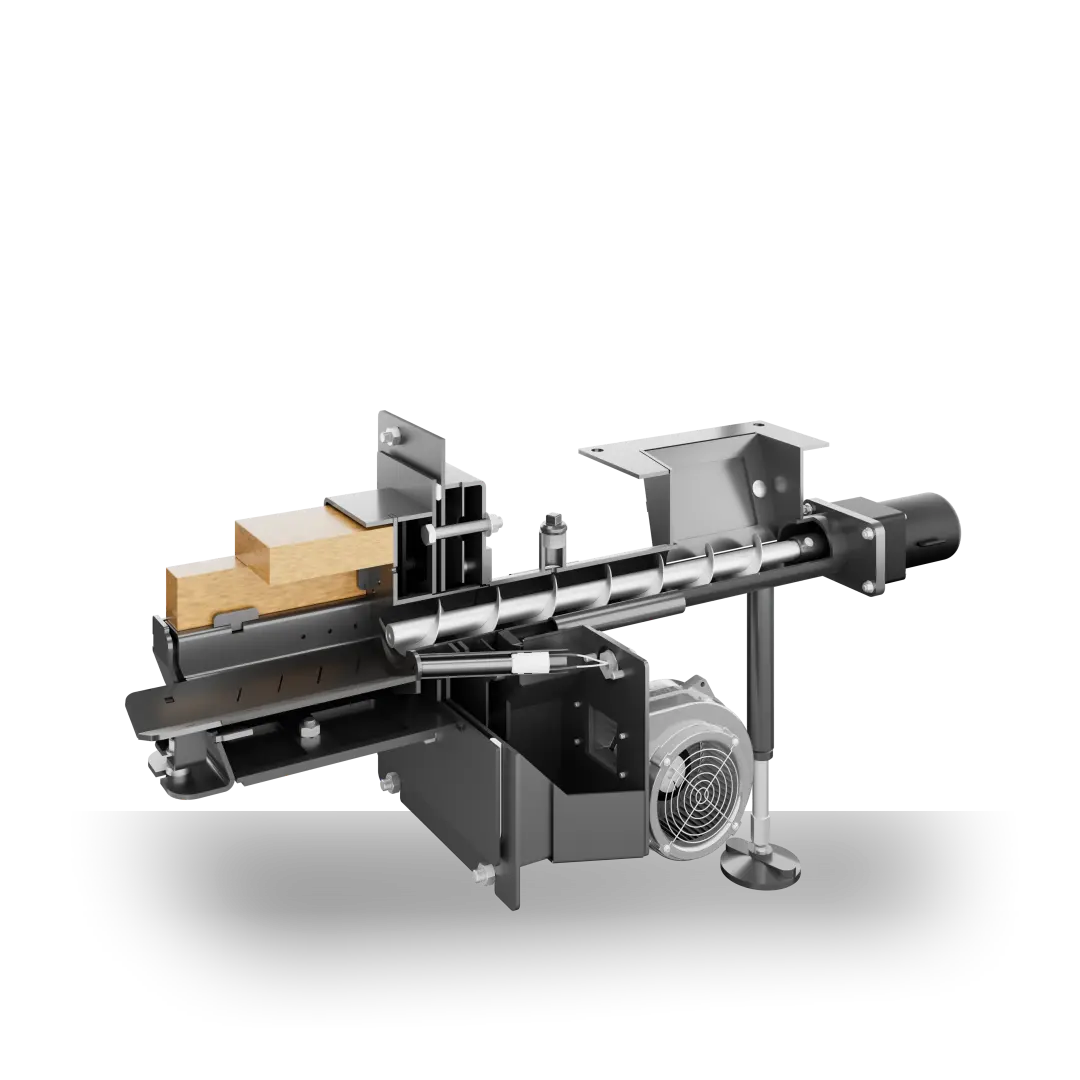

Construction of a central heating boiler

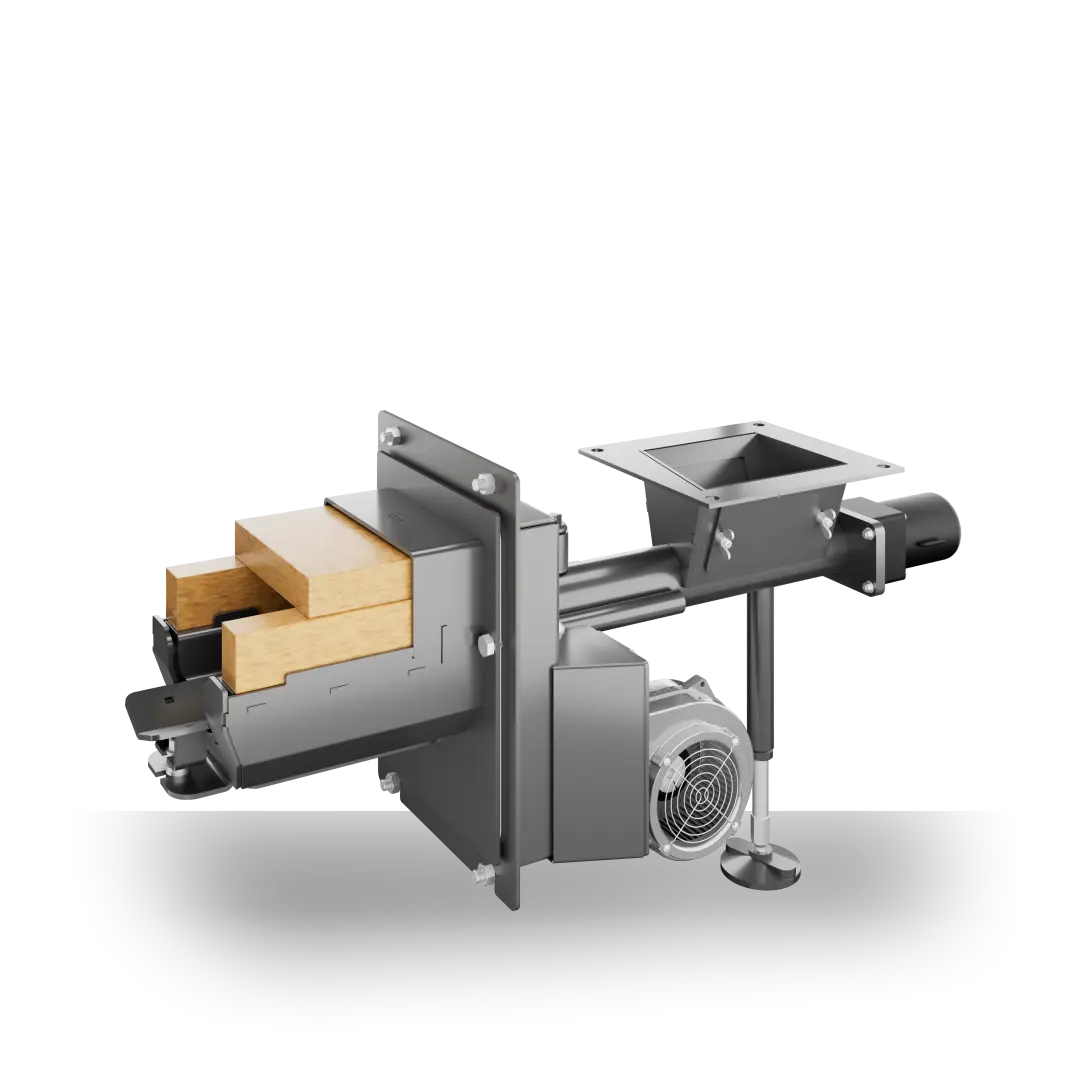

Automatic feeder

- Maintenance-free fuel supply - pellets are automatically transported from the tank to the burner, eliminating the need for manual feeding.

- Quiet and smooth operation - solid construction and high-quality mechanisms ensure reliability and minimize noise.

- Time saving - the large capacity of the tank allows for long-term operation of the boiler without the need for frequent fuel refilling.

The automatic feeder guarantees the continuity of the combustion process and optimal boiler efficiency, with minimal involvement on the part of the user.

Limit switch

Swirlers

Increases heat exchange efficiency - swirlers cause turbulence in the exhaust gases, which improves heat transfer to the water jacket.

Reduces fuel consumption - better heat exchange means lower energy losses and more economical operation of the boiler.

Horizontal and vertical convection channels | shelf

Flue outlet at the back of the boiler

Fireman

Any interference with the boiler’s design is prohibited and will void the warranty. Attempts to install additional grates or components that allow the combustion of fuels other than those specified by the manufacturer, outside the automatic furnace, are prohibited.

Ecology and savings

Pellet burner

- Fast ignition – the igniter reaches high temperatures in a short time.

- Long service life – high resistance to temperature and mechanical wear.

Gutter Burner

Modern Control

Controls

PLATINUM PELLET Controller

- One mixing circuit C.O.1 with a room thermostat – allows for precise adjustment of the heating water temperature and rooms.

- Pump (C.W.U., C.O., additional) – manages additional heating zones such as underfloor heating or domestic hot water control.

- RTC clock – allows programming of the weekly boiler operation schedule.

- Weather control – allows programming of boiler operation modes depending on the weather or time of day.

- FuzzyLogic & PID – monitors the boiler operation, allows for current viewing of operating parameters and diagnostics of possible irregularities.

The controller is also compatible with the ecoNET300 internet module, which allows for remote control of the boiler using a smartphone or computer from anywhere.

Accessories for central heating boilers

Equipmentadditional

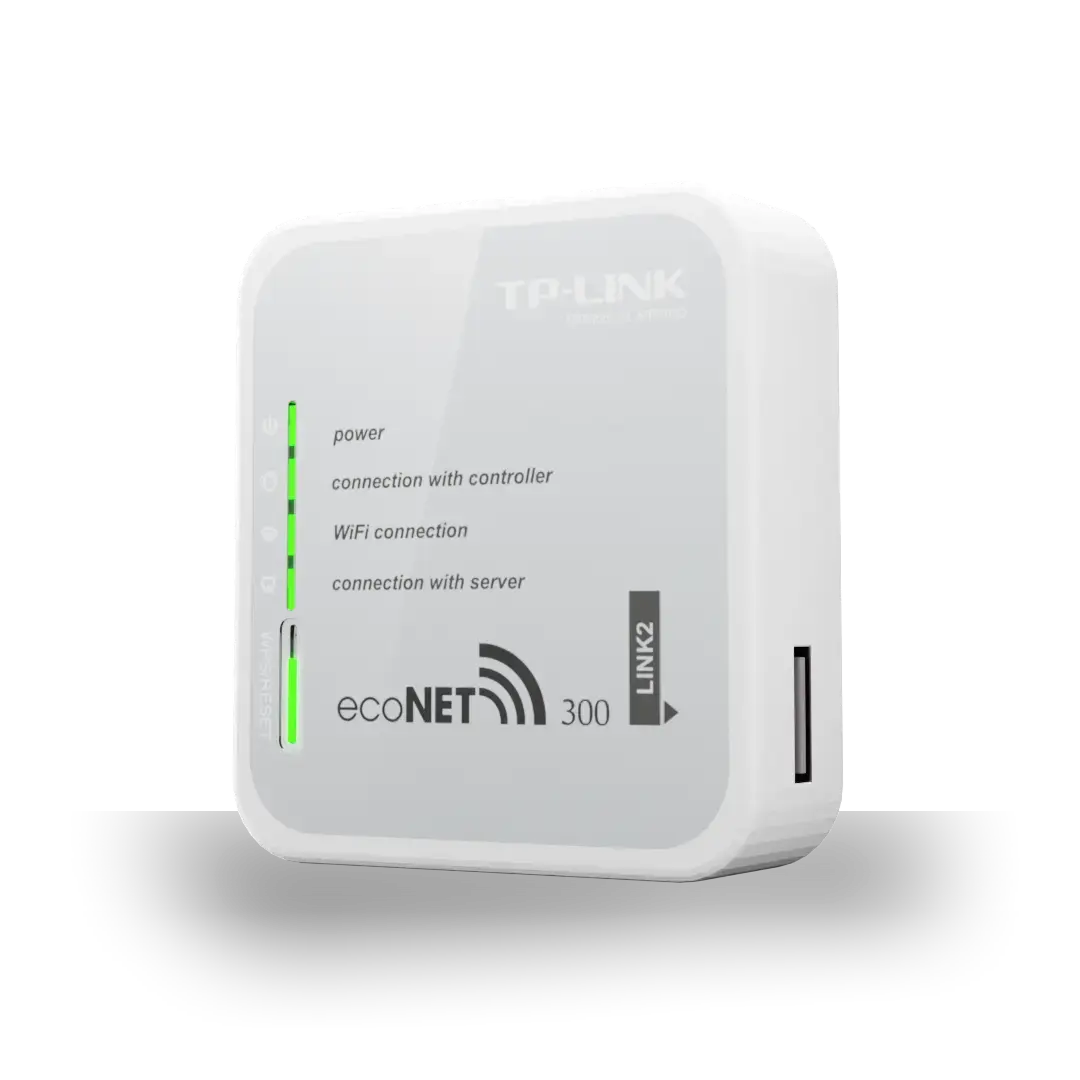

ecoNET300 Internet Module

The ecoNET300 Internet Module is a modern device that allows remote control of the boiler via the Internet. Thanks to the dedicated application, the user has full access to monitoring the boiler's operating parameters, temperature settings and the heating system's operating schedule.

Platinum Touch x40 Room Thermostat

The Platinum Touch x40 room thermostat is an elegant, touch-sensitive device that allows for precise temperature management in your home. Equipped with a large, clear display, it provides intuitive operation and weekly programming.

Platinum Touch x80 Room Thermostat

Platinum Touch x80 is an advanced version of the thermostat, offering even greater programming and control options for the heating system. It has a larger touch screen and additional functions, such as control of several heating circuits or the ability to integrate with smart home systems.

Platinum ecoSTER100 room thermostat

The Platinum ecoSTER100 thermostat allows you to remotely control your boiler from a convenient user interface. The device not only regulates the temperature in rooms, but also controls the operation of heating circuits and utility water.

ecoMAX 360B Expansion Module – Platinum B/C

The B/C expansion module enables control of additional heating circuits, pumps and actuators. It is an ideal solution for installations requiring flexible management of multiple heating zones in a building, providing full control over the heat in different rooms.

Lambda Sensor

The Lambda Sensor is an advanced device for controlling the combustion process, which automatically optimizes the amount of air supplied to the combustion chamber.

Technical data

Parameters

Parameters

SEG BIO 15

SEG BIO 20

SEG BIO 30

SEG BIO 40

SEG BIO 50

SEG BIO 75

Emissions / Efficiency

Parameter

SEG BIO 15

SEG BIO 20

SEG BIO 30

SEG BIO 40

SEG BIO 50

SEG BIO 75

Certificates

Parameter

SEG BIO 15

SEG BIO 20

SEG BIO 30

SEG BIO 40

SEG BIO 50

SEG BIO 75

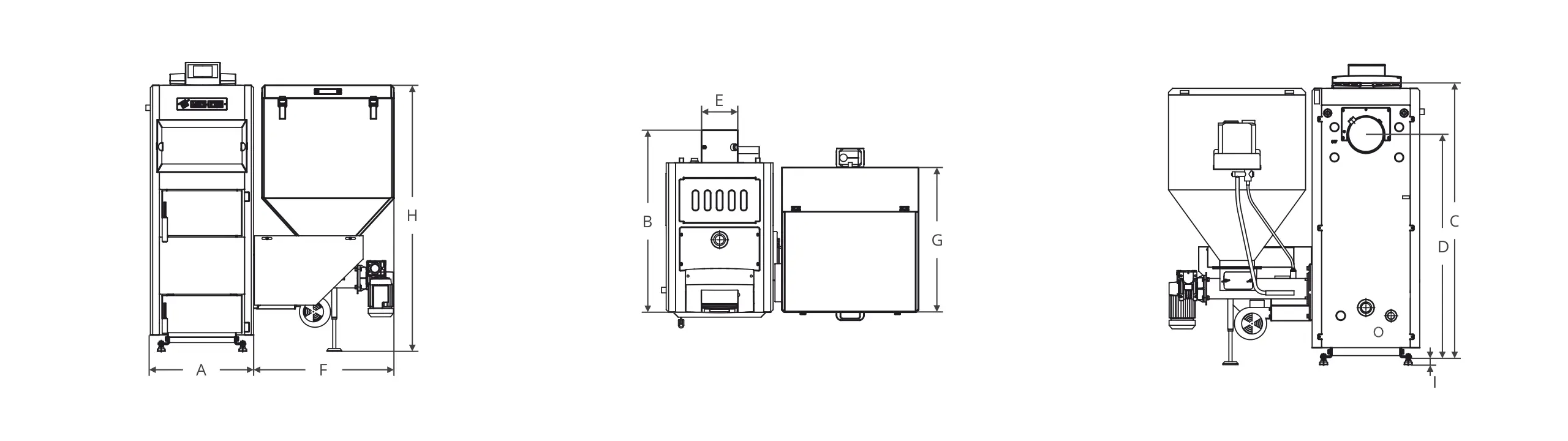

Dimensions

Dimension

SEG BIO 15

SEG BIO 20

SEG BIO 30

SEG BIO 40

SEG BIO 50

SEG BIO 75

Documentation

Certificate

Energy label

Product card 2015/1187

Contact with advisor

- Paweł Czepiel

- EExport Manager

- Region: Europe, World

- Language: English, Russian

- Mon-Fri 7:00-15:00

- +48 663 45 32 22

- +48 85 711 94 54 ext. 17

- p.czepiel@metalfach.com.pl

Our products

Pellet boilers

Wood gasification boilers

Wood boilers

Eco-pea coal boilers

Hydraulic clutches and central heating distributors

Agricultural machinery

Do you have a question about our offer?

Contact our representative.

Offer

Shopping and advice

Service and services

Contact

- METAL-FACH Technika Grzewcza Sp. z o.o.

- st. Sikorskiego 66, 16-100 Sokółka, Poland

- NIP: 545-182-60-12

- REGON: 523566030

- Mon-Fri 07:00-15:00

- Phone: +48 85 711 94 54

- sprzedaz@metalfach.com.pl

2026 © Copyright METAL-FACH Technika Grzewcza Sp. z o.o.