BOILER

HOLZ FLAME MAX

Essential Information

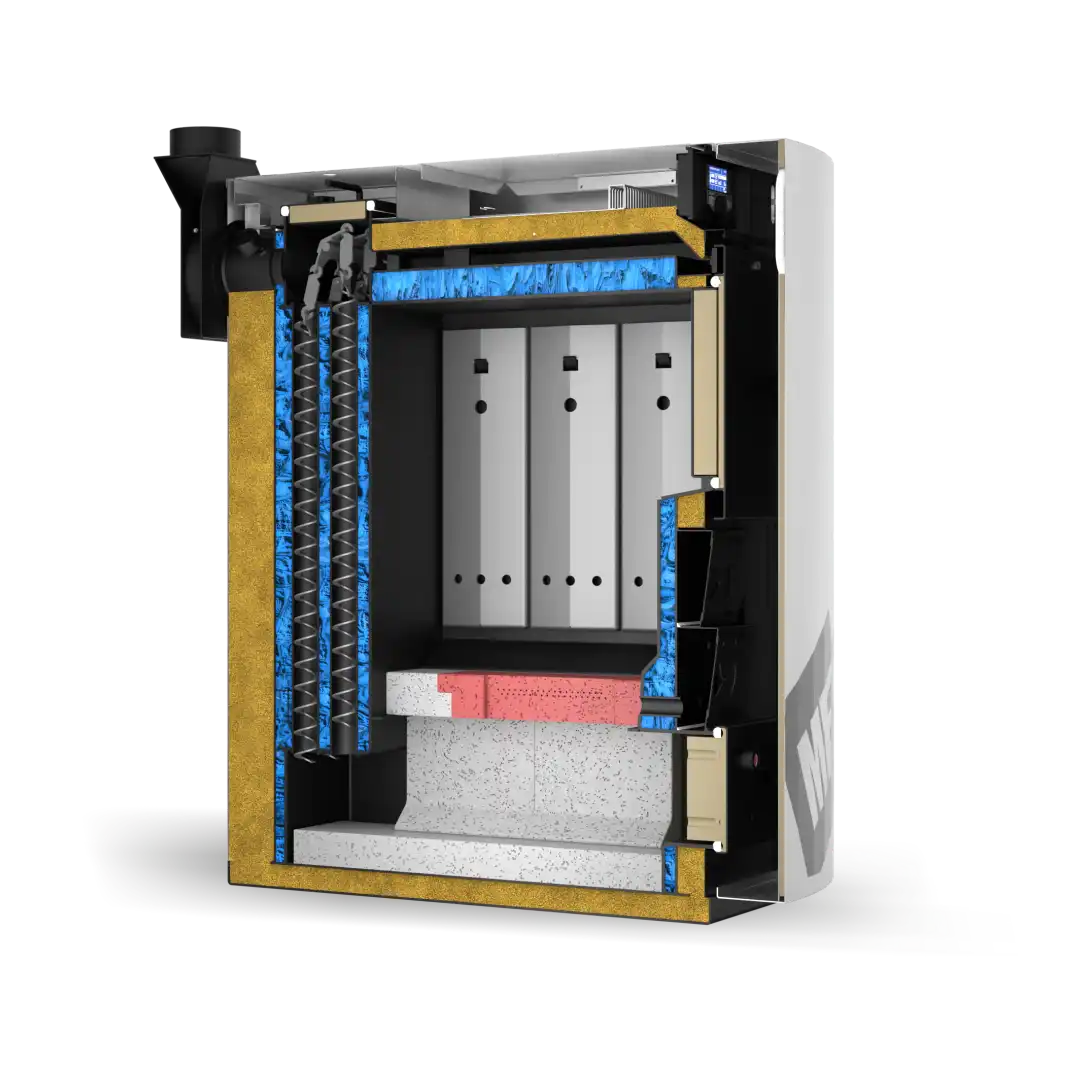

The HOLZ FLAME MAX boiler was designed for small boiler rooms. This device is considered a wood gasification boiler. The boiler is designed for efficient burning of lump firewood in accordance with standard 303-5:2021-09. It is equipped with a ceramic catalyst that regulates the combustion process to make it as efficient as possible. The boiler is additionally equipped with mechanical cleaning of convection channels.

Available powers: 30kW

Fuel: firewood, pieces

Certificates: EcoDesign | 5 class

Energy class: A +

Key benefits

Heat exchanger

Vertical convection channels | tubular

Effective design adapted to mechanical cleaning of the exchanger. The construction of the boiler exchanger ensures high heat reception from the furnace.

Effective design adapted to mechanical cleaning of the exchanger. The construction of the boiler exchanger ensures high heat reception from the furnace.

Flue exit

At the top

The boiler structure has been designed in such a way that the flue outlet is at the top. The use of such a solution in a central heating boiler allows for indirect discharge of the flue to the chimney.

The boiler structure has been designed in such a way that the flue outlet is at the top. The use of such a solution in a central heating boiler allows for indirect discharge of the flue to the chimney.

Exhaust fan

The exhaust fan effectively supports the natural draft of exhaust gases in the boiler.

Swirlers

With mechanical cleaning

The swirlers installed in the convection channels, connected to the mechanical cleaning system, effectively reduce the exhaust gas outlet velocity. Thanks to systematic cleaning, the boiler maintains a constant high heat reception through the water jacket. The use of mechanical cleaning of convection channels contributes to reducing fuel demand.

The swirlers installed in the convection channels, connected to the mechanical cleaning system, effectively reduce the exhaust gas outlet velocity. Thanks to systematic cleaning, the boiler maintains a constant high heat reception through the water jacket. The use of mechanical cleaning of convection channels contributes to reducing fuel demand.

Ceramic catalysts

It acts as a regulator, stabilizing the wood combustion process, which ensures higher efficiency, and also contributes to exhaust gas purification. By controlling the temperature and composition of exhaust gases, the ceramic catalytic converter helps maintain optimal combustion conditions.

Automatic regulation of secondary and primary air

Air is sucked in through six holes to fully burn the fuel. The amount of secondary and primary air is automatically adjusted.

Steel screens

The use of steel screens in the combustion chamber improves the efficiency of the combustion process. The screens raise the temperature in the combustion chamber and stop particles floating above the furnace, burning them out. The thermal efficiency of the boiler increases, and the exhaust gases reduce the amount of environmentally harmful compounds to a minimum.

Buffer tank

Additional equipment

Ensures optimal boiler operating conditions. The boiler can operate at optimal power and excess heat is collected in the buffer. The home’s heating system draws as much heat from the buffer as it needs at a given moment.

ATTENTION!

Central heating boiler can be installed in a heating system only together with a buffer tank. The tank is not included in the price of the boiler.

Boiler control

Adjust the boiler operation and room temperature to your individual needs. The ecoMAX860D1-H controller is programmed to automate all processes related to heating your home. The owner specifies the temperature he wants in the apartment, and the controller will optimize combustion in this respect. It all depends on the preferences of the user and household members!

The most important features:

Domestic hot water pump or diverter valve for zoned charging

DHW circulation pump

2 mixing circuits with pumps

Auxiliary buffer loading/unloading pump

Exhaust fan

Weather control

PID

Buffer tank

Additional equipment:

ecoNET 300 internet module

Control operation, monitor and compare statistics thanks to the connection of the boiler controller with the internet module. Gain access to boiler control from your mobile phone, tablet or computer. The online module is not only a remote control, it also records and registers the progress of home heating. Thanks to the ecoNET internet module (wired, Wi-Fi), you can gain control over your expenses and nothing will surprise you anymore!

Control operation, monitor and compare statistics thanks to the connection of the boiler controller with the internet module. Gain access to boiler control from your mobile phone, tablet or computer. The online module is not only a remote control, it also records and registers the progress of home heating. Thanks to the ecoNET internet module (wired, Wi-Fi), you can gain control over your expenses and nothing will surprise you anymore!

Platinum B module (buffer control, additional two heating circuits, 2x pump, 2x mixer, 2x thermostat)

Manual ignition

Firewood – hornbeam logs (chips) with humidity Wc=15-20%. Properly seasoned wood is an ecological fuel that meets all standards. It is completely natural, combustion produces biodegradable ash. By burning properly seasoned wood, we produce small amounts of harmful compounds into the atmosphere.

Boiler technical data

| PARAMETERS | UNIT S.I. | HOLZ FLAME MAX 30 |

| Nominal thermal power | [kW] | 30 |

| Boiler power range | [kW] | 30 |

| Heatable surface* | [m2] | 300-450 |

| Water capacity | [L] | 145 |

| Maximum working pressure | [bar] | 3 |

| Maximum working temperature | [°C] | 80 |

| Test pressure | [bar] | 4,5 |

| Glade circumference (tribe) | [cm] | 10-15 |

| Log length (strain) | [cm] | 50 |

| Fuel | [-] | firewood, pieces |

| Temperature controller setting range | [°C] | 60-80 (every 1°C) |

| Chimney draft required | [Pa] | – |

| Heat storage capacity (buffer) | [L] | 500 |

| Boiler weight | [kg] | 342 |

*A new building with very good thermal insulation was adopted for the calculations.

Certificates, class, boiler emission

| PARAMETERS | UNIT S.I. | HOLZ FLAME MAX 30 |

| Ecodesign | [-] | Yes |

| Boiler class | [-] | 5 |

| Energy class | [-] | A+ |

| Seasonal particulate emissions | [mg/m3] | – |

| Efficiency for nominal power | [%] | 93,6 |

| Nominal emissivity of the particulate matter | [mg/m3] | – |

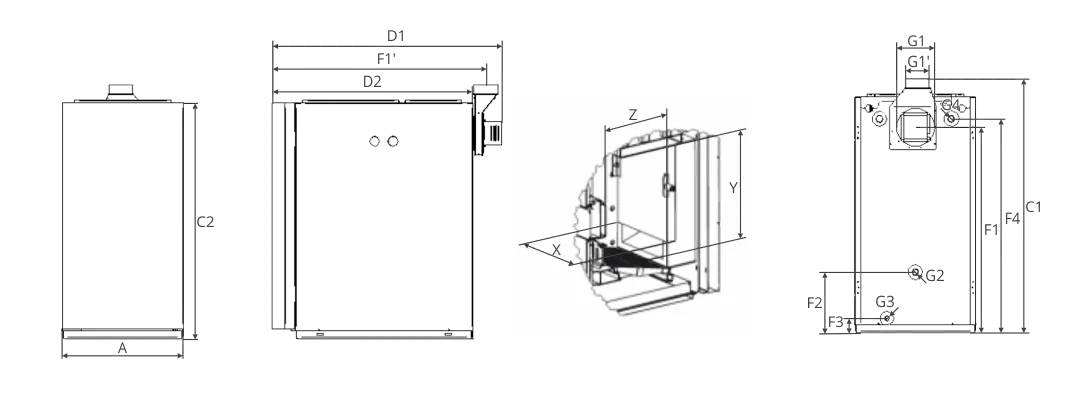

Boiler dimensions

| DIMENSION | UNIT S.I. | HOLZ FLAME MAX 30 |

| A | [mm] | 650 |

| B1 | [mm] | – |

| B2 | [mm] | – |

| C1 | [mm] | 1375 |

| C2 | [mm] | 1275 |

| D1 | [mm] | 1235 |

| D2 | [mm] | – |

| E | [mm] | – |

| F1 | [mm] | 1152 |

| F1′ | [mm] | – |

| F2 | [mm] | 328 |

| F3 | [mm] | – |

| F4 | [mm] | – |

| G1 | [mm] | 150 |

| G1′ | [mm] | 180 |

| G2 | [cal] | 1 |

| G3 | [cal] | 1/2 |

| G4 | [cal] | 1 |

| H | [mm] | 30 |

| W | [mm] | – |

| X | [mm] | 356 |

| Y | [mm] | 590 |

| Z | [mm] | 550 |

Boiler documentation

DTR instruction

| Technical and operational documentation | Download |

Driver manual

| ecoMAX860D1-H controller manual | Download |

EcoDesign certificate

| The boiler complies with the requirements of the EcoDesign standard | Download |

Energy label

| A + energy class | Download |

Product sheet in accordance with EU regulation 2015/1187

| According to EU Regulation 2015/1187 supplementing Directive 2009/125 / EC of the European Parliament and of the Council | Download |

Product sheet in accordance with EU regulation 2015/1189

| Compliant with the EU Commission Regulation 2015/1189 of April 28, 2015 | Download |

Foreign sales

Paweł Czepiel

Export manager

Language: Russian, English

Monday-Friday (7:00 a.m. - 3:00 p.m.)

Phone:

+48 663 45 32 22

+48 85 711 94 54 ext. 17

E-mail:

p.czepiel@metalfach.com.pl

METAL-FACH Technika Grzewcza Sp. z o.o. reserves the right to introduce changes to the technical parameters, equipment and specifications of the offered goods without prior notice.

General contact:

Opening hours:

- Mon.-Fri. 7:00a.m.-3:00p.m.

- Phone: +48 85 711 94 54 int. 17

- E-mail: p.czepiel@metalfach.com.pl

General contact:

Service contact:

Opening hours:

- Mon.-Fri. 7:00a.m.–3:00 p.m.

- Phone: +48 85 711 94 54 int. 17

- E-mail: p.czepiel@metalfach.com.pl

Address data:

METAL-FACH Technika Grzewcza

Sp. z o.o.

- st. Sikorskiego 66, 16-100 Sokółka, Poland

- NIP: 545-182-60-12

- REGON: 523566030