BOILER

SEM DUOPELL

Limited quantity, product available while supplies last!

The most important information

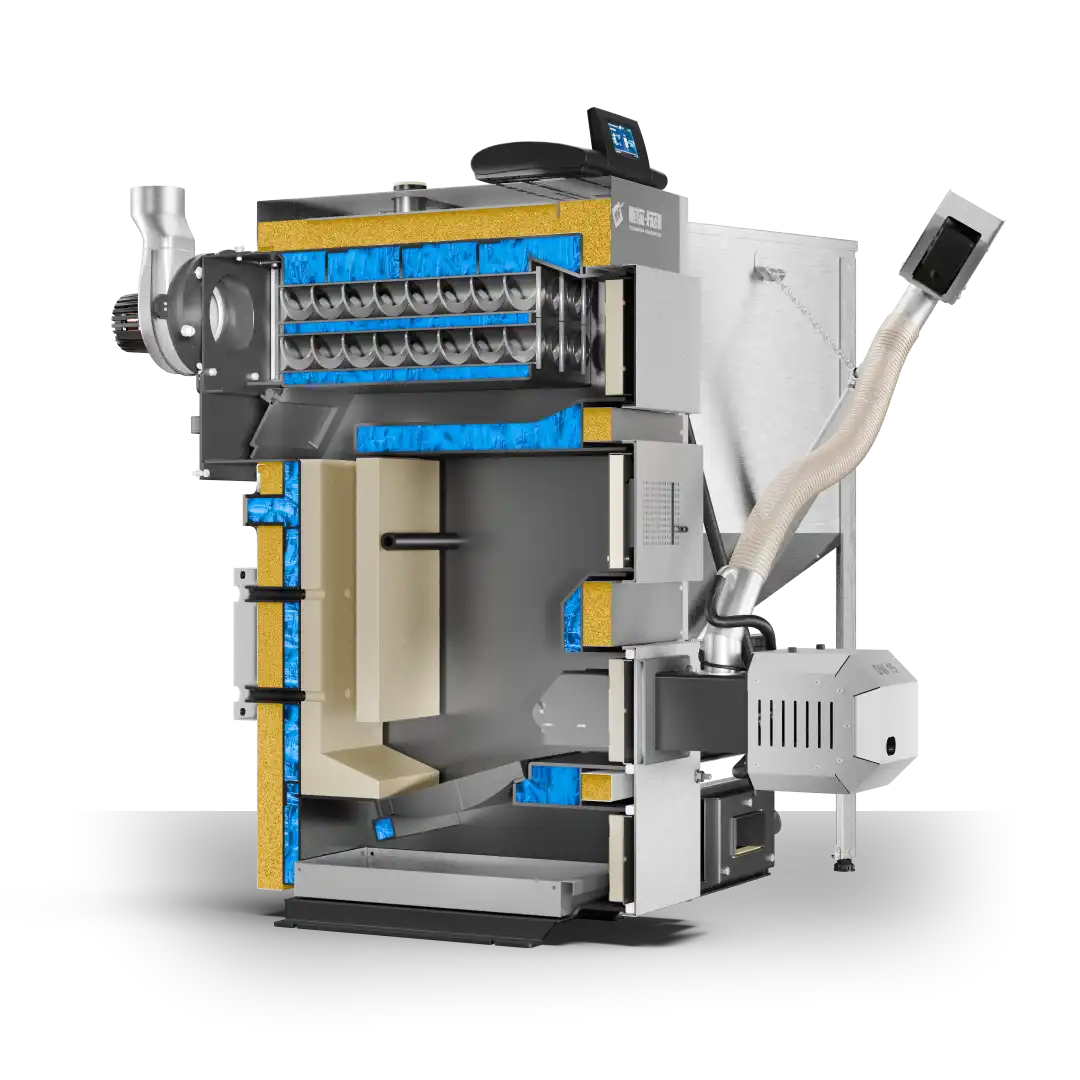

The SEM DUOPELL boiler was designed for small boiler rooms. This device is considered a wood gasification boiler. An additional advantage of the boiler is its charging tank, which can be placed on any side, making it easier to fit into small boiler rooms. The SEM DUOPELL boiler qualifies as a wood gasification boiler, but it also enables pellet combustion in automatic mode. The boiler is designed for efficient burning of pieces firewood in accordance with the 303-5:2021-09 standard, and wood pallet in accordance with the PN EN 303-5:2021-09 standard. It is equipped with a self-cleaning burner. Pellet igniter cooperating with the RTC clock, turning on and off the boiler according to the schedule, reducing the number of activities that need to be performed on the boiler to almost zero. Thanks to the possibility of connecting the ecoNET300 internet module to the boiler, you can manage the boiler functions from a phone, tablet or computer.

SEM DUOPELL wood gasification boiler, with the option of burning pellets!

Available power: 16,23kW

The most important advantages

Heat exchanger

Effective design adapted for quick cleaning of the exchanger at the front. The construction of the boiler exchanger ensures high heat reception from the furnace.

Flue exit

The boiler structure has been designed in such a way that the flue outlets are located at the back. The use of such a solution in a central heating boiler allows the flue to be discharged directly into the chimney.

Exhaust gas temperature sensor

Secondary and primary air intake

Air intakes must be completely closed when using a boiler with a feeder.

Smoke exhaust flap

The smoke exhaust flap must be completely closed when using a boiler with a feeder.

Exhaust fan

The exhaust fan effectively supports the natural draft of exhaust gases in the boiler.

The air is regulated using an exhaust and blowing fan when using a boiler with a feeder.

Automatic feeder

Boiler control

Key Features:

FuzzyLogic & PID

Optional equipment:

Control operation, monitor, compare statistics by connecting the boiler controller with the Internet module. Gain access to boiler control from a mobile phone, tablet or computer. The Internet module is not only a remote control, it is also a recording and register of the course of heating the house. Thanks to the ecoNET internet module (wired, wi-fi) you can gain control over your expenses and nothing will surprise you anymore!

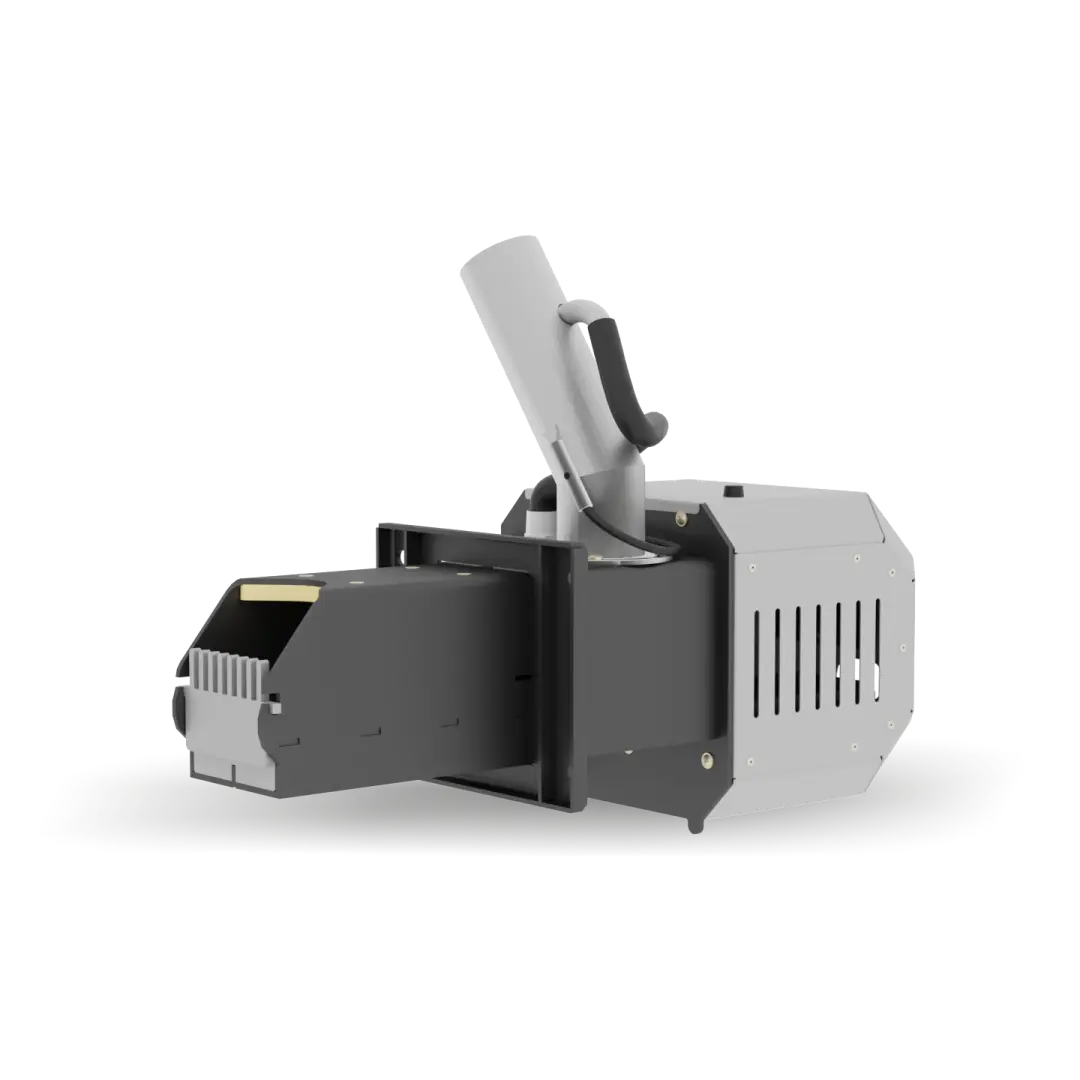

Pellet burner

Burner DW Self-cleaning – for pellets

Quick firing up of the hearth and automatic cleaning of the hearth from ashes. The burner is equipped with an automatic ceramic pellet igniter and has been designed for regular, self-cleaning of ash. The design of the burner allows you to quickly reach a high temperature of the boiler. All functions of cleaning the ash from the furnace and fuel dosing can be set according to the current needs of the user.

Key Features:

Ecological fuel, which is pellets, also known as biomass, is made by pressing wood waste such as sawdust or shavings. This fully natural fuel turns into biodegradable ash when burned.

Forget about manually firing up the boiler. Just one click and the automatic ceramic igniter ignites the fuel fed to the burner. The automatic igniter combined with the RTC clock allows you to program the entire working week of the device. The device operation timer can be set separately for SUMMER and WINTER modes.

The burner regularly cleans itself of ash, which reduces the need for manual cleaning to a minimum. The use of this technology prevents the combustion chamber from becoming clogged with ash, and also allows the burner itself to remain in excellent efficiency.

Boiler technical data

| PARAMETERS | S.I. UNIT | SEM DUOPELL 16 |

| Nominal heat output | [kW] | 16 |

| Boiler power range | [kW] | 4,8-16 |

| Area that can be heated* | [m2] | 72-240 |

| water capacity | [L] | 71 |

| Maximum working pressure | [bar] | 3 |

| Maximum operating temperature | [°C] | 80 |

| Test pressure | [bar] | 4,5 |

| Fuel tank capacity | [L] | 230 |

| Fuel tank capacity | [kg] | 138 |

| Primary fuel | [-] | firewood, pieces |

| Additional fuel | [-] | pellet Φ6-8mm |

| Electrical connection | [-] | 1A; ~230V; 50Hz / 4A; ~230V; 50Hz |

| Electric power consumption | [W] | – |

| Temperature controller setting range | [°C] | 60-80 (every 1°C) |

| Chimney draft required | [Pa] | 20 |

| Thermal storage tank capacity | [l] | 600 |

| Boiler weight | [kg] | 342 |

*A new building with very good thermal insulation was assumed for the calculations.

| PARAMETERS | S.I. UNIT | SEM DUOPELL 23 |

| Nominal heat output | [kW] | 23 |

| Boiler power range | [kW] | 6,9-23 |

| Area that can be heated* | [m2] | 103,5-345 |

| water capacity | [L] | 97 |

| Maximum working pressure | [bar] | 3 |

| Maximum operating temperature | [°C] | 80 |

| Test pressure | [bar] | 4,5 |

| Fuel tank capacity | [L] | – |

| Fuel tank capacity | [kg] | – |

| Primary fuel | [-] | firewood, pieces |

| Additional fuel | [-] | pellet Φ6-8mm |

| Electrical connection | [-] | 1A; ~230V; 50Hz / 4A; ~230V; 50Hz |

| Electric power consumption | [W] | – |

| Temperature controller setting range | [°C] | 60-80 (every 1°C) |

| Chimney draft required | [Pa] | 18 |

| Thermal storage tank capacity | [l] | 920 |

| Boiler weight | [kg] | 342 |

*A new building with very good thermal insulation was assumed for the calculations.

Certificates, class, boiler emissivity

| PARAMETERS | S.I. UNIT | SEM DUOPELL 16 |

| Ecodesign (Eco Project) | [-] | Yes |

| Boiler class | [-] | 5 |

| Energy class | [-] | A+ |

| Seasonal emissivity of particulate matter | [mg/m3] | 20 |

| Efficiency for nominal power | [%] | 89,2 |

| Particulate nominal emissivity | [mg/m3] | 20 |

| Efficiency for minimum power | [%] | – |

| Minimum emissivity of particulates | [mg/m3] | – |

| PARAMETERS | S.I. UNIT | SEM DUOPELL 16 |

| Ecodesign (Eco Project) | [-] | Yes |

| Boiler class | [-] | 5 |

| Energy class | [-] | A+ |

| Seasonal emissivity of particulate matter | [mg/m3] | 20 |

| Efficiency for nominal power | [%] | 91,0 |

| Particulate nominal emissivity | [mg/m3] | 18 |

| Efficiency for minimum power | [%] | 89,2 |

| Minimum emissivity of particulates | [mg/m3] | 20 |

| PARAMETERS | S.I. UNIT | SEM DUOPELL 23 |

| Ecodesign (Eco Project) | [-] | Yes |

| Boiler class | [-] | 5 |

| Energy class | [-] | A+ |

| Seasonal emissivity of particulate matter | [mg/m3] | 19 |

| Efficiency for nominal power | [%] | 90,1 |

| Particulate nominal emissivity | [mg/m3] | 19 |

| Efficiency for minimum power | [%] | – |

| Minimum emissivity of particulates | [mg/m3] | – |

| PARAMETERS | S.I. UNIT | SEM DUOPELL 23 |

| Ecodesign (Eco Project) | [-] | Yes |

| Boiler class | [-] | 5 |

| Energy class | [-] | A+ |

| Seasonal emissivity of particulate matter | [mg/m3] | 18 |

| Efficiency for nominal power | [%] | 90,5 |

| Particulate nominal emissivity | [mg/m3] | 16 |

| Efficiency for minimum power | [%] | 89,6 |

| Minimum emissivity of particulates | [mg/m3] | 19 |

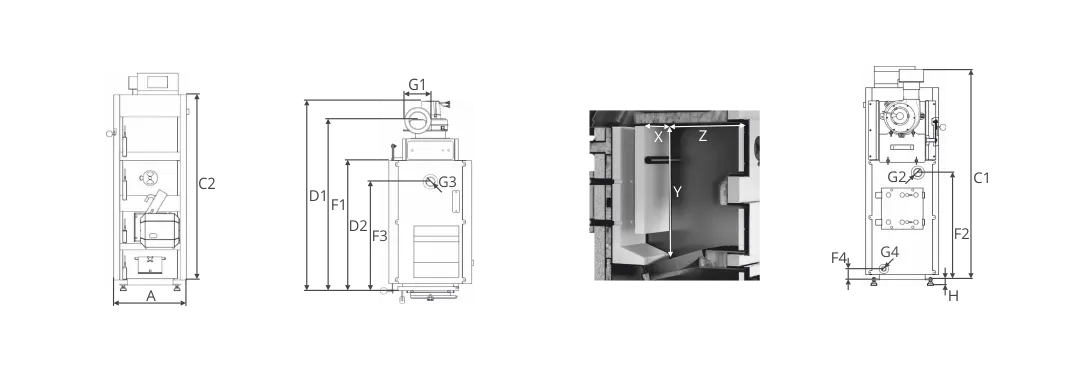

Boiler dimensions

| DIMENSION | S.I. UNIT | SEM DUOPELL 16 |

| A | [mm] | 490 |

| B1 | [mm] | – |

| B2 | [mm] | – |

| C1 | [mm] | 1380 |

| C2 | [mm] | 1260 |

| D1 | [mm] | 1070 |

| D2 | [mm] | 730 |

| E | [mm] | – |

| F1 | [mm] | 735 |

| F2 | [mm] | 713 |

| F3 | [mm] | 470 |

| F4 | [mm] | 82 |

| G1 | [mm] | 159 |

| G2 | [cal] | 1 1/2 |

| G3 | [cal] | 1 1/2 |

| G4 | [cal] | 3/4 |

| H | [mm] | 30 |

| H | [mm] | 290 |

| H | [mm] | 690 |

| H | [mm] | 390 |

| DIMENSION | S.I. UNIT | SEM DUOPELL 23 |

| A | [mm] | 495 |

| B1 | [mm] | – |

| B2 | [mm] | – |

| C1 | [mm] | 1664 |

| C2 | [mm] | 1540 |

| D1 | [mm] | 1144 |

| D2 | [mm] | 785 |

| E | [mm] | – |

| F1 | [mm] | 825 |

| F2 | [mm] | 780 |

| F3 | [mm] | 637 |

| F4 | [mm] | 97 |

| G1 | [mm] | 159 |

| G2 | [cal] | 1 1/2 |

| G3 | [cal] | 1 1/2 |

| G4 | [cal] | 3/4 |

| H | [mm] | 30 |

| H | [mm] | 290 |

| H | [mm] | 690 |

| H | [mm] | 390 |

Boiler documentation

DTR manual

| Technical and operational documentation for the SEM DUOPELL 16 boiler | Download |

Driver Manual

| PLATINUM PELLET controller manual | Download |

EcoDesign certificate

| Boiler compliant with the requirements of the EcoDesign standard (EcoDesign) – SEM DUOPELL 16 | Download |

| Boiler compliant with the requirements of the EcoDesign standard (EcoDesign) – SEM DUOPELL 16 with manual feeding | Download |

| Boiler compliant with the requirements of the EcoDesign standard (EcoDesign) – SEM DUOPELL 23 with manual feeding | Download |

Product fiche in accordance with EU Regulation 2015/1187

| In accordance with EU Regulation 2015/1187 supplementing Directive 2009/125/EC of the European Parliament and of the Council – SEM DUOPELL 16 | Download |

| In accordance with EU Regulation 2015/1187 supplementing Directive 2009/125/EC of the European Parliament and of the Council – SEM DUOPELL 16 with manual feeding | Download |

| In accordance with EU Regulation 2015/1187 supplementing Directive 2009/125/EC of the European Parliament and of the Council – SEM DUOPELL 23 with manual feeding | Download |

Product sheet according to EU Regulation 2015/1189

| Compliant with the Regulation of the EU Commission 2015/1189 of April 28, 2015. – SEM DUOPELL 16 | Download |

| Compliant with the Regulation of the EU Commission 2015/1189 of April 28, 2015. – SEM DUOPELL 16 with manual feeding | Download |

| Compliant with the Regulation of the EU Commission 2015/1189 of April 28, 2015. – SEM DUOPELL 23 with manual feeding | Download |

Foreign sales

Paweł Czepiel

Export manager

Language: Russian, English

Monday-Friday (7:00 a.m. – 3:00 p.m.)

Phone:

+48 663 45 32 22

+48 85 711 94 54 ext. 17

E-mail:

p.czepiel@metalfach.com.pl

Dane adresowe:

METAL-FACH Technika Grzewcza

Sp. z o.o.

- ul. Sikorskiego 66, 16-100 Sokółka, Polska

- NIP: 545-182-60-12

- REGON: 523566030

Kontakt ogólny:

Otwarte:

- Pon.-Pt. 07: 00-15:00

- Tel. +48 85 711 94 54

- E-mail: sprzedaz@metalfach.com.pl

Kontakt serwis:

- Pon.-Pt. 7:00-20:00

- Sob. 8:00-14:00

- Niedz. 10:00-14:00

- Tel. +48 85 711 94 56

- E-mail: serwis.kotly@metalfach.com.pl

Kontakt serwis:

Pompy ciepła:

- Pon.-Pt. 7:00-15:00

- Tel. +48 85 711 94 54 wew. 12

- E-mail: serwis.pompy@metalfach.com.pl

Dofinansowanie:

Social Media:

2010-2024 © Copyright METAL-FACH Technika Grzewcza Sp. z o.o. | Wszelkie prawa zastrzeżone.