BOILER

SE

Essential information

Key benefits

Heat exchanger

Effective design for quick cleaning of the exchanger from the front. The design of the boiler exchanger ensures high heat removal from the furnace.

Flue outlet

The structure of the boiler has been designed in such a way that the flue outlet is at the rear. The use of such a solution in a central heating boiler allows the flue to be directly led out to the chimney.

Secondary air damper

Blower fan

Effectively supports the natural exhaust gas flow in the boiler. Additionally, it prevents smoke from escaping from the boiler to the boiler room. It also requires a driver to be installed.

Draft regulator

Depending on the temperature of the medium, it controls the flap regulating the air supply to the boiler combustion chamber.

Boiler control

Simple boiler control

Adjust the boiler operation and room temperature to your individual needs. The DK SYSTEM-420 controller is programmed in such a way as to automate partially the processes related to heating your home. The owner specifies the temperature he wants to have in the room, and the controller will optimize combustion in this respect.

Key features:

Manual firing up

Manual ignition and fuel loading

We can load firewood or coal into the combustion chamber. Wood, unlike coal, properly seasoned is an ecological fuel that meets all standards. It is completely natural, as a result of combustion, biodegradable ash is produced. By burning properly seasoned wood, we produce a small amount of harmful compounds into the atmosphere.

Technical data of the boiler

| PARAMETERS | UNIT S.I. | SE 60 |

| Nominal thermal power | [kW] | 60 |

| Boiler power range | [kW] | 60 |

| Heatable surface* | [m2] | 600 |

| Heating area | [m2] | 3,4 |

| Water capacity | [L] | 90 |

| Maximum working pressure | [bar] | 1,5 |

| Maximum working temperature | [°C] | 95 |

| Test pressure | [bar] | 4 |

| Fuel | [-] | wood, coal |

| Chimney draft required | [Pa] | – |

| Boiler weight | [kg] | 438 |

* A new building with very good thermal insulation was adopted for the calculations.

| PARAMETERS | UNIT S.I. | SE 75 |

| Nominal thermal power | [kW] | 75 |

| Boiler power range | [kW] | 75 |

| Heatable surface* | [m2] | 600-750 |

| Heating area | [m2] | 3,8 |

| Water capacity | [L] | 105 |

| Maximum working pressure | [bar] | 1,5 |

| Maximum working temperature | [°C] | 95 |

| Test pressure | [bar] | 4 |

| Fuel | [-] | wood, coal |

| Chimney draft required | [Pa] | – |

| Boiler weight | [kg] | 480 |

* A new building with very good thermal insulation was adopted for the calculations.

| PARAMETERS | UNIT S.I. | SE 95 |

| Nominal thermal power | [kW] | 95 |

| Boiler power range | [kW] | 95 |

| Heatable surface* | [m2] | 750-950 |

| Heating area | [m2] | 4,5 |

| Water capacity | [L] | 115 |

| Maximum working pressure | [bar] | 1,5 |

| Maximum working temperature | [°C] | 95 |

| Test pressure | [bar] | 4 |

| Fuel | [-] | wood, coal |

| Chimney draft required | [Pa] | – |

| Boiler weight | [kg] | 521 |

* A new building with very good thermal insulation was adopted for the calculations.

| PARAMETERS | UNIT S.I. | SE 120 |

| Nominal thermal power | [kW] | 120 |

| Boiler power range | [kW] | 120 |

| Heatable surface* | [m2] | 950-1200 |

| Heating area | [m2] | 6,9 |

| Water capacity | [L] | 260 |

| Maximum working pressure | [bar] | 1,5 |

| Maximum working temperature | [°C] | 95 |

| Test pressure | [bar] | 4 |

| Fuel | [-] | wood, coal |

| Chimney draft required | [Pa] | – |

| Boiler weight | [kg] | 850 |

* A new building with very good thermal insulation was adopted for the calculations.

| PARAMETERS | UNIT S.I. | SE 150 |

| Nominal thermal power | [kW] | 150 |

| Boiler power range | [kW] | 150 |

| Heatable surface* | [m2] | 1200-1500 |

| Heating area | [m2] | 8,0 |

| Water capacity | [L] | 290 |

| Maximum working pressure | [bar] | 1,5 |

| Maximum working temperature | [°C] | 95 |

| Test pressure | [bar] | 4 |

| Fuel | [-] | wood, coal |

| Chimney draft required | [Pa] | – |

| Boiler weight | [kg] | 1015 |

* A new building with very good thermal insulation was adopted for the calculations.

| PARAMETERS | UNIT S.I. | SE 200 |

| Nominal thermal power | [kW] | 200 |

| Boiler power range | [kW] | 200 |

| Heatable surface* | [m2] | 1500-2000 |

| Heating area | [m2] | 9,2 |

| Water capacity | [L] | 316 |

| Maximum working pressure | [bar] | 1,5 |

| Maximum working temperature | [°C] | 95 |

| Test pressure | [bar] | 4 |

| Fuel | [-] | wood, coal |

| Chimney draft required | [Pa] | – |

| Boiler weight | [kg] | 1090 |

* A new building with very good thermal insulation was adopted for the calculations.

| PARAMETERS | UNIT S.I. | SE 250 |

| Nominal thermal power | [kW] | 250 |

| Boiler power range | [kW] | 250 |

| Heatable surface* | [m2] | 2000-2500 |

| Heating area | [m2] | 10 |

| Water capacity | [L] | 330 |

| Maximum working pressure | [bar] | 1,5 |

| Maximum working temperature | [°C] | 95 |

| Test pressure | [bar] | 4 |

| Fuel | [-] | wood, coal |

| Chimney draft required | [Pa] | – |

| Boiler weight | [kg] | 1160 |

* A new building with very good thermal insulation was adopted for the calculations.

| PARAMETERS | UNIT S.I. | SE 350 |

| Nominal thermal power | [kW] | 350 |

| Boiler power range | [kW] | 350 |

| Heatable surface* | [m2] | 2500-3500 |

| Heating area | [m2] | 18,32 |

| Water capacity | [L] | 713 |

| Maximum working pressure | [bar] | 1,5 |

| Maximum working temperature | [°C] | 95 |

| Test pressure | [bar] | 4 |

| Fuel | [-] | wood, coal |

| Chimney draft required | [Pa] | – |

| Boiler weight | [kg] | 2050 |

* A new building with very good thermal insulation was adopted for the calculations.

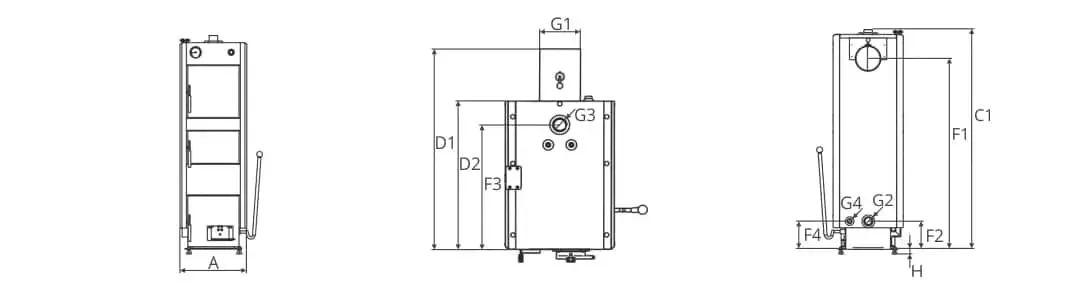

Boiler dimensions

| DIMENSION | UNIT S.I. | SE 60 |

| A | [mm] | 530 |

| B1 | [mm] | – |

| B2 | [mm] | – |

| C1 | [mm] | 1530 |

| C2 | [mm] | – |

| D1 | [mm] | 960 |

| D2 | [mm] | 800 |

| E | [mm] | – |

| F1 | [mm] | 1330 |

| F2 | [mm] | 225 |

| F3 | [mm] | 584 |

| F4 | [mm] | 175 |

| G1 | [mm] | 200 |

| G2 | [cal] | 1 1/2 |

| G3 | [cal] | 1 1/2 |

| G4 | [cal] | 3/4 |

| H | [mm] | 30 |

| DIMENSION | UNIT S.I. | SE 75 |

| A | [mm] | 580 |

| B1 | [mm] | – |

| B2 | [mm] | – |

| C1 | [mm] | 1530 |

| C2 | [mm] | – |

| D1 | [mm] | 960 |

| D2 | [mm] | 800 |

| E | [mm] | – |

| F1 | [mm] | 1330 |

| F2 | [mm] | 225 |

| F3 | [mm] | 584 |

| F4 | [mm] | 175 |

| G1 | [mm] | 200 |

| G2 | [cal] | 1 1/2 |

| G3 | [cal] | 1 1/2 |

| G4 | [cal] | 3/4 |

| H | [mm] | 30 |

| DIMENSION | UNIT S.I. | SE 95 |

| A | [mm] | 680 |

| B1 | [mm] | – |

| B2 | [mm] | – |

| C1 | [mm] | 1530 |

| C2 | [mm] | – |

| D1 | [mm] | 960 |

| D2 | [mm] | 800 |

| E | [mm] | – |

| F1 | [mm] | 1330 |

| F2 | [mm] | 225 |

| F3 | [mm] | 584 |

| F4 | [mm] | 185 |

| G1 | [mm] | 200 |

| G2 | [cal] | 1 1/2 |

| G3 | [cal] | 1 1/2 |

| G4 | [cal] | 3/4 |

| H | [mm] | 30 |

| DIMENSION | UNIT S.I. | SE 120 |

| A | [mm] | 770 |

| B1 | [mm] | – |

| B2 | [mm] | – |

| C1 | [mm] | 1830 |

| C2 | [mm] | – |

| D1 | [mm] | 1550 |

| D2 | [mm] | 1120 |

| E | [mm] | – |

| F1 | [mm] | 1690 |

| F2 | [mm] | 195 |

| F3 | [mm] | 480 |

| F4 | [mm] | 100 |

| G1 | [mm] | 250 |

| G2 | [cal] | 2 |

| G3 | [cal] | 2 |

| G4 | [cal] | 3/4 |

| H | [mm] | 30 |

| DIMENSION | UNIT S.I. | SE 150 |

| A | [mm] | 860 |

| B1 | [mm] | – |

| B2 | [mm] | – |

| C1 | [mm] | 1910 |

| C2 | [mm] | – |

| D1 | [mm] | 1580 |

| D2 | [mm] | 1170 |

| E | [mm] | – |

| F1 | [mm] | 1780 |

| F2 | [mm] | 180 |

| F3 | [mm] | 660 |

| F4 | [mm] | 155 |

| G1 | [mm] | 250 |

| G2 | [cal] | 2 |

| G3 | [cal] | 2 |

| G4 | [cal] | 3/4 |

| H | [mm] | 30 |

| DIMENSION | UNIT S.I. | SE 200 |

| A | [mm] | 860 |

| B1 | [mm] | – |

| B2 | [mm] | – |

| C1 | [mm] | 2110 |

| C2 | [mm] | – |

| D1 | [mm] | 1580 |

| D2 | [mm] | 1170 |

| E | [mm] | – |

| F1 | [mm] | 1980 |

| F2 | [mm] | 180 |

| F3 | [mm] | 655 |

| F4 | [mm] | 155 |

| G1 | [mm] | 250 |

| G2 | [cal] | 2 |

| G3 | [cal] | 2 |

| G4 | [cal] | 3/4 |

| H | [mm] | 30 |

| DIMENSION | UNIT S.I. | SE 250 |

| A | [mm] | 860 |

| B1 | [mm] | – |

| B2 | [mm] | – |

| C1 | [mm] | 2110 |

| C2 | [mm] | – |

| D1 | [mm] | 1580 |

| D2 | [mm] | 1270 |

| E | [mm] | – |

| F1 | [mm] | 1980 |

| F2 | [mm] | 180 |

| F3 | [mm] | 655 |

| F4 | [mm] | 155 |

| G1 | [mm] | 250 |

| G2 | [cal] | 2 |

| G3 | [cal] | 2 |

| G4 | [cal] | 3/4 |

| H | [mm] | 30 |

| DIMENSION | UNIT S.I. | SE 350 |

| A | [mm] | 1202 |

| B1 | [mm] | – |

| B2 | [mm] | – |

| C1 | [mm] | 2030 |

| C2 | [mm] | – |

| D1 | [mm] | 2230 |

| D2 | [mm] | 1726 |

| E | [mm] | – |

| F1 | [mm] | 1553 |

| F2 | [mm] | 382 |

| F3 | [mm] | 711 |

| F4 | [mm] | 344 |

| G1 | [mm] | 350 |

| G2 | [mm] | 101,6 |

| G3 | [mm] | 101,6 |

| G4 | [cal] | 1 1/4 |

| H | [mm] | 30 |

Boiler documentation

Foreign sales

Paweł Czepiel

Export manager

Language: Russian, English

Monday-Friday (7:00 a.m. – 3:00 p.m.)

Phone:

+48 663 45 32 22

+48 85 711 94 54 ext. 17

E-mail:

p.czepiel@metalfach.com.pl

General contact:

Opening hours:

- Mon.-Fri. 7:00a.m.-3:00p.m.

- Phone: +48 85 711 94 54 int. 17

- E-mail: p.czepiel@metalfach.com.pl

General contact:

Service contact:

Opening hours:

- Mon.-Fri. 7:00a.m.–3:00 p.m.

- Phone: +48 85 711 94 54 int. 17

- E-mail: p.czepiel@metalfach.com.pl

Address data:

METAL-FACH Technika Grzewcza

Sp. z o.o.

- st. Sikorskiego 66, 16-100 Sokółka, Poland

- NIP: 545-182-60-12

- REGON: 523566030