BOILER

SEMAX BASIC

The most important information

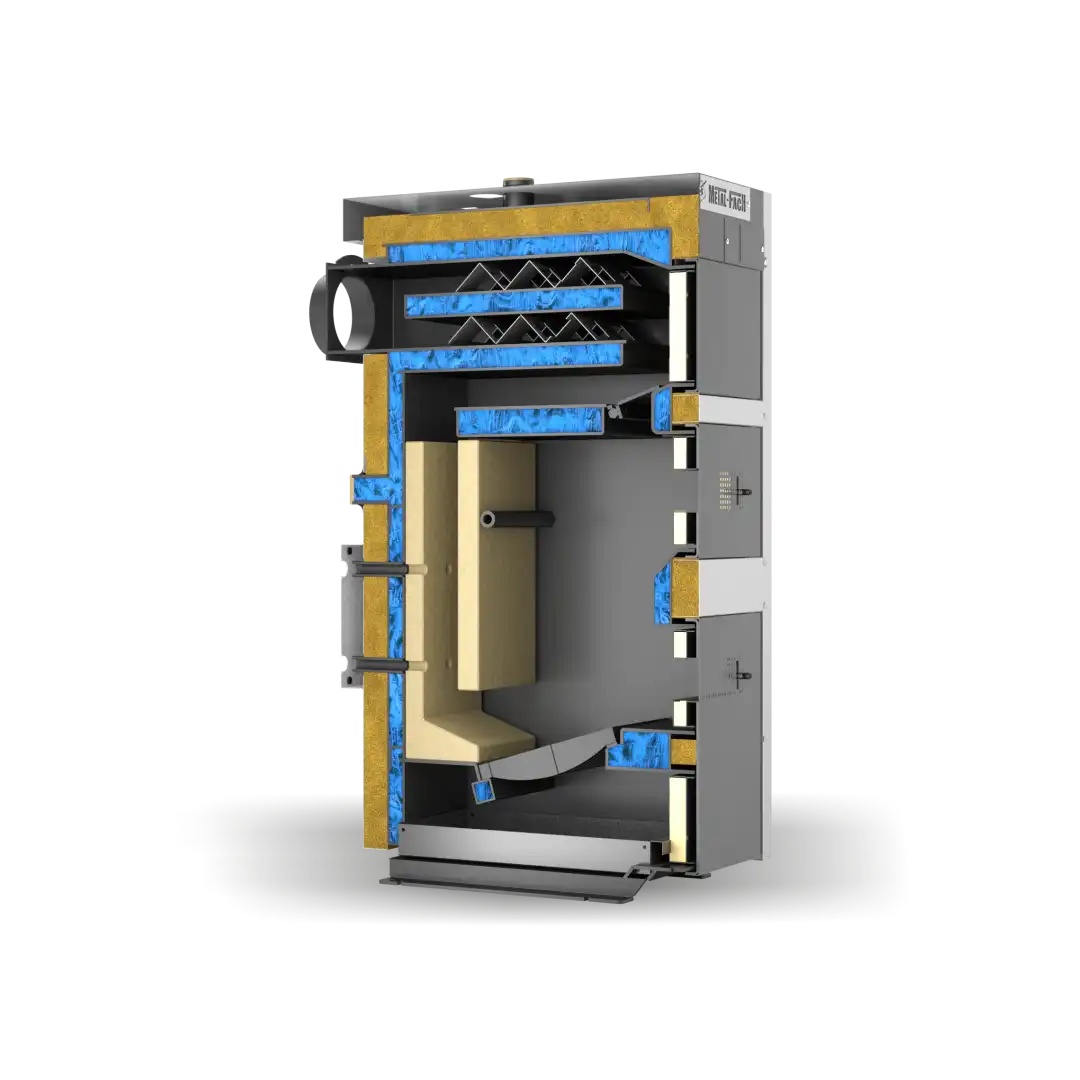

The SEMAX BASIC boiler is a boiler that gasifies pieces firewood in accordance with the 303-5:2021-09 standard. It is an ideal solution dedicated to people who have large stocks of properly stored firewood – hornbeam logs (logs) with a humidity of Wc=15-20%. . Operating our device at nominal power allows for better use of fuel and, as a result, cleaner exhaust gases emitted into the atmosphere. Additionally, the boiler is equipped with a draft regulator and a thermometer enabling regulation of combustion and operation of the device. For proper operation of the entire system, the boiler must be connected to a buffer receiving excess heat.

The most important advantages

Heat exchanger

Effective design adapted for quick cleaning of the exchanger from the front. The construction of the boiler exchanger ensures high heat removal from the furnace.

Flue exit

The construction of the boiler has been designed in such a way that the flue exits are located at the back. The use of such a solution in the central heating boiler allows for direct discharge of the flue into the chimney.

Thrust regulator

Mechanical thermometer

Secondary and primary air intake

Smoke vent

Turbulators

Ceramic channel

Buffer tank

It ensures optimal working conditions of the boiler. The boiler can operate with optimal power, and the excess heat is stored in the buffer. The house’s heating system draws as much heat from the buffer as it needs at a given moment.

ATTENTION!

Central heating boiler can be installed in the heating system, only together with the buffer tank. The tank is not included in the price of the boiler.

Manual ignition

Boiler technical data

| PARAMETERS | S.I. UNIT | SEMAX BASIC 15 |

| Nominal heat output | [kW] | 15 |

| Boiler power range | [kW] | 15 |

| Area that can be heated* | [m2] | 150-225 |

| Water capacity | [L] | 71 |

| Maximum working pressure | [bar] | 3 |

| Maximum operating temperature | [°C] | 80 |

| Test pressure | [bar] | 4,5 |

| Circumference of glades (tribe) | [cm] | 30-40 |

| Billet length (tribe) | [cm] | 26 |

| Fuel | [-] | firewood, pieces |

| Temperature controller setting range | [°C] | 60-80 (every 1°C) |

| Chimney draft required | [Pa] | 23 |

| Heat accumulator capacity (buffer) | [L] | 555 |

| Boiler weight | [kg] | 342 |

*The calculations assumed a new building with very good thermal insulation.

| PARAMETERS | S.I. UNIT | SEMAX BASIC 20 |

| Nominal heat output | [kW] | 20 |

| Boiler power range | [kW] | 20 |

| Area that can be heated* | [m2] | 200-300 |

| Water capacity | [L] | 77 |

| Maximum working pressure | [bar] | 3 |

| Maximum operating temperature | [°C] | 80 |

| Test pressure | [bar] | 4,5 |

| Circumference of glades (tribe) | [cm] | 30-40 |

| Billet length (tribe) | [cm] | 36 |

| Fuel | [-] | firewood, pieces |

| Temperature controller setting range | [°C] | 60-80 (every 1°C) |

| Chimney draft required | [Pa] | 22 |

| Heat accumulator capacity (buffer) | [L] | 780 |

| Boiler weight | [kg] | 390 |

*Do obliczeń przyjęto nowy budynek o bardzo dobrej izolacji cieplnej.

| PARAMETERS | S.I. UNIT | SEMAX BASIC 30 |

| Nominal heat output | [kW] | 30 |

| Boiler power range | [kW] | 30 |

| Area that can be heated* | [m2] | 300-450 |

| Water capacity | [L] | 99 |

| Maximum working pressure | [bar] | 3 |

| Maximum operating temperature | [°C] | 80 |

| Test pressure | [bar] | 4,5 |

| Circumference of glades (tribe) | [cm] | 30-40 |

| Billet length (tribe) | [cm] | 34 |

| Fuel | [-] | firewood, pieces |

| Temperature controller setting range | [°C] | 60-80 (every 1°C) |

| Chimney draft required | [Pa] | 25 |

| Heat accumulator capacity (buffer) | [L] | 1230 |

| Boiler weight | [kg] | 415 |

*Do obliczeń przyjęto nowy budynek o bardzo dobrej izolacji cieplnej.

| PARAMETERS | S.I. UNIT | SEMAX BASIC 40 |

| Nominal heat output | [kW] | 40 |

| Boiler power range | [kW] | 40 |

| Area that can be heated* | [m2] | 400-600 |

| Water capacity | [L] | 116 |

| Maximum working pressure | [bar] | 3 |

| Maximum operating temperature | [°C] | 80 |

| Test pressure | [bar] | 4,5 |

| Circumference of glades (tribe) | [cm] | 30-40 |

| Billet length (tribe) | [cm] | 34 |

| Fuel | [-] | firewood, pieces |

| Temperature controller setting range | [°C] | 60-80 (every 1°C) |

| Chimney draft required | [Pa] | 28 |

| Heat accumulator capacity (buffer) | [L] | 1680 |

| Boiler weight | [kg] | 500 |

*Do obliczeń przyjęto nowy budynek o bardzo dobrej izolacji cieplnej.

Certificates, class, boiler emissivity

| PARAMETERS | S.I. UNIT | SEMAX BASIC 15 |

| Ecodesign (Eco Project) | [-] | Yes |

| Boiler class | [-] | 5 |

| Energy class | [-] | A+ |

| Seasonal emissivity of particulate matter | [mg/m3] | 20 |

| Efficiency for nominal power | [%] | 90 |

| Particulate nominal emissivity | [mg/m3] | 20 |

| PARAMETERS | S.I. UNIT | SEMAX BASIC 20 |

| Ecodesign (Eco Project) | [-] | Yes |

| Boiler class | [-] | 5 |

| Energy class | [-] | A+ |

| Seasonal emissivity of particulate matter | [mg/m3] | 18 |

| Efficiency for nominal power | [%] | 88,7 |

| Particulate nominal emissivity | [mg/m3] | 17 |

| PARAMETERS | S.I. UNIT | SEMAX BASIC 30 |

| Ecodesign (Eco Project) | [-] | Yes |

| Boiler class | [-] | 5 |

| Energy class | [-] | A+ |

| Seasonal emissivity of particulate matter | [mg/m3] | 19 |

| Efficiency for nominal power | [%] | 89,1 |

| Particulate nominal emissivity | [mg/m3] | 19 |

| PARAMETERS | S.I. UNIT | SEMAX BASIC 40 |

| Ecodesign (Eco Project) | [-] | Yes |

| Boiler class | [-] | 5 |

| Energy class | [-] | A+ |

| Seasonal emissivity of particulate matter | [mg/m3] | 19 |

| Efficiency for nominal power | [%] | 89,2 |

| Particulate nominal emissivity | [mg/m3] | 19 |

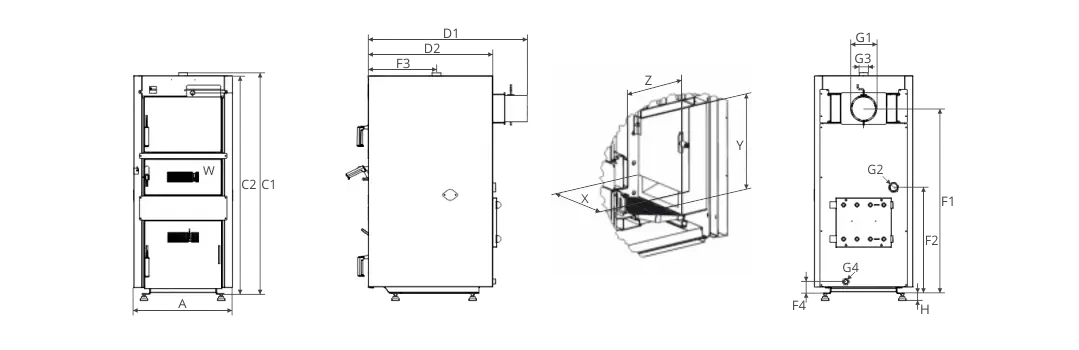

Boiler dimensions

| DIMENSION | S.I. UNIT | SEMAX BASIC 15 |

| A | [mm] | 490 |

| B1 | [mm] | – |

| B2 | [mm] | – |

| C1 | [mm] | 1275 |

| C2 | [mm] | 1255 |

| D1 | [mm] | 957 |

| D2 | [mm] | 725 |

| E | [mm] | – |

| F1 | [mm] | 1050 |

| F2 | [mm] | 713 |

| F3 | [mm] | 368 |

| F4 | [mm] | 80 |

| G1 | [mm] | 159 |

| G2 | [cal] | 1 1/2 |

| G3 | [cal] | 1 1/2 |

| G4 | [cal] | 3/4 |

| H | [mm] | 30 |

| W | [mm] | 290×200 |

| X | [mm] | 290 |

| Y | [mm] | 515 |

| Z | [mm] | 345 |

| DIMENSION | S.I. UNIT | SEMAX BASIC 20 |

| A | [mm] | 520 |

| B1 | [mm] | – |

| B2 | [mm] | – |

| C1 | [mm] | 1275 |

| C2 | [mm] | 1255 |

| D1 | [mm] | 1070 |

| D2 | [mm] | 835 |

| E | [mm] | – |

| F1 | [mm] | 1050 |

| F2 | [mm] | 713 |

| F3 | [mm] | 455 |

| F4 | [mm] | 80 |

| G1 | [mm] | 159 |

| G2 | [cal] | 1 1/2 |

| G3 | [cal] | 1 1/2 |

| G4 | [cal] | 3/4 |

| H | [mm] | 30 |

| W | [mm] | 290×200 |

| X | [mm] | 290 |

| Y | [mm] | 515 |

| Z | [mm] | 445 |

| DIMENSION | S.I. UNIT | SEMAX BASIC 30 |

| A | [mm] | 560 |

| B1 | [mm] | – |

| B2 | [mm] | – |

| C1 | [mm] | 1480 |

| C2 | [mm] | 1460 |

| D1 | [mm] | 1070 |

| D2 | [mm] | 835 |

| E | [mm] | – |

| F1 | [mm] | 1240 |

| F2 | [mm] | 713 |

| F3 | [mm] | 455 |

| F4 | [mm] | 80 |

| G1 | [mm] | 177 |

| G2 | [cal] | 1 1/2 |

| G3 | [cal] | 1 1/2 |

| G4 | [cal] | 3/4 |

| H | [mm] | 30 |

| W | [mm] | 340×200 |

| X | [mm] | 340 |

| Y | [mm] | 590 |

| Z | [mm] | 420 |

| DIMENSION | S.I. UNIT | SEMAX BASIC 40 |

| A | [mm] | 660 |

| B1 | [mm] | – |

| B2 | [mm] | – |

| C1 | [mm] | 1480 |

| C2 | [mm] | 1460 |

| D1 | [mm] | 1065 |

| D2 | [mm] | 835 |

| E | [mm] | – |

| F1 | [mm] | 1240 |

| F2 | [mm] | 713 |

| F3 | [mm] | 455 |

| F4 | [mm] | 80 |

| G1 | [mm] | 177 |

| G2 | [cal] | 1 1/2 |

| G3 | [cal] | 1 1/2 |

| G4 | [cal] | 3/4 |

| H | [mm] | 30 |

| W | [mm] | 440×200 |

| X | [mm] | 440 |

| Y | [mm] | 590 |

| Z | [mm] | 420 |

Boiler documentation

DTR manual

EcoDesign certificate

Energy label

| Energy class A+ | Download |

Product fiche in accordance with EU Regulation 2015/1187

| In accordance with EU Regulation 2015/1187 supplementing Directive 2009/125/EC of the European Parliament and of the Council | Download |

Product sheet according to EU Regulation 2015/1189

| Complies with the Regulation of the EU Commission 2015/1189 of April 28, 2015 | Download |

Foreign sales

Paweł Czepiel

Export manager

Language: Russian, English

Monday-Friday (7:00 a.m. – 3:00 p.m.)

Phone:

+48 663 45 32 22

+48 85 711 94 54 ext. 17

E-mail:

p.czepiel@metalfach.com.pl

Kontakt ogólny:

Otwarte:

- Pon.-Pt. 07: 00-15:00

- Tel. +48 85 711 94 54

- E-mail: sprzedaz@metalfach.com.pl

Social Media:

Kontakt serwis:

Kotły c.o.:

- Pon.-Pt. 7:00-20:00

- Sob. 8:00-16:00

- Niedz. 10:00-14:00

- Tel. +48 85 711 94 56

- E-mail: serwis.kotly@metalfach.com.pl

Kontakt serwis:

Pompy ciepła:

- Pon.-Pt. 7:00-15:00

- Tel. +48 85 711 94 54 wew. 12

- E-mail: serwis.pompy@metalfach.com.pl

Dane adresowe:

METAL-FACH Technika Grzewcza

Sp. z o.o.

- ul. Sikorskiego 66, 16-100 Sokółka, Polska

- NIP: 545-182-60-12

- REGON: 523566030