BOILER

SMART EKO PLUS

The most important information

The most important advantages

Heat exchanger

Effective design adapted for quick cleaning of the exchanger from the front. The construction of the boiler exchanger ensures high heat removal from the furnace.

Flue exit

The boiler structure has been designed in such a way that the flue exits are located at the back of the boiler or at the top. The use of such a solution in a central heating boiler allows for direct or indirect removal of the flue to the chimney.

Limit switch

Highly efficient combustion chamber

Automatic feeder

Turbulators

Boiler control

Key features:

Optional equipment:

Control operation, monitor, compare statistics by connecting the boiler controller with the Internet module. Gain access to boiler control from a mobile phone, tablet or computer. The Internet module is not only a remote control, it is also a recording and register of the course of heating the house. Thanks to the ecoNET internet module (wired, wi-fi) you can gain control over your expenses and nothing will surprise you anymore!

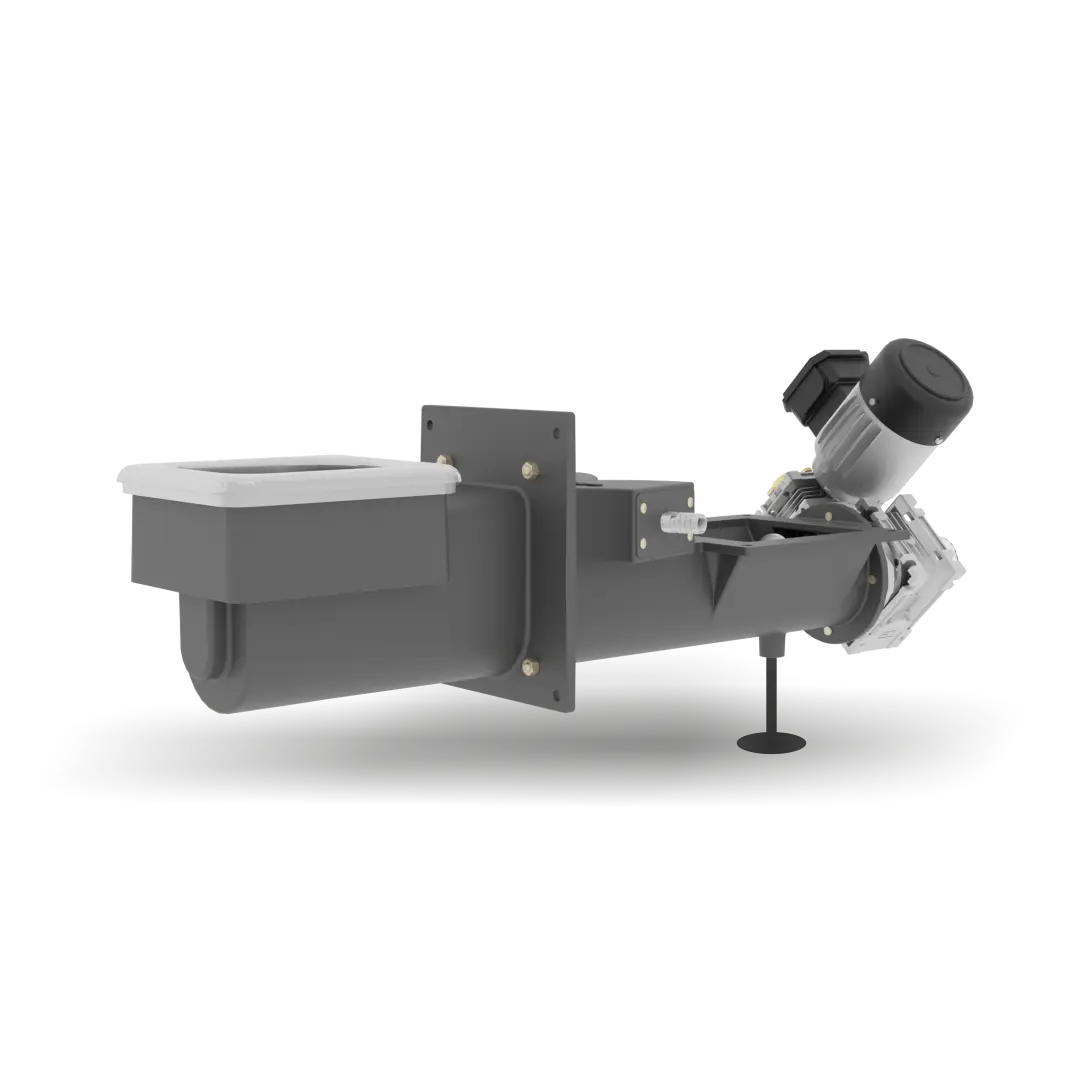

Burner for eco-pea coal

Cast iron burner Ekoenergia II – for eco-pea coal

Cast-iron carburizing system for the boiler with manual firing up of the furnace. The eco pea burner and its components in contact with high temperature are made of cast iron. Thanks to the use of this material for the construction of the burner, these elements are more resistant to corrosion than ordinary steel, even if we use moist fuel. The cast-iron elements of the burner also reduce the noise of the feeder operation. The burner and the feeding screw are made of ductile cast iron, resistant primarily to abrasion and high temperature. A burner constructed in this way will work reliably for many years.

Key features:

Ecological fuel from the depths of the earth. Eco pea fuel is produced on the basis of hard coal. The prefix “eco” means that it meets the stricter gas emission standards. The eco-pea fuel has a negligible sulfur content, a small amount of ash and low humidity. When burning, it produces much less harmful compounds than ordinary coal.

Forget about manually firing up the boiler. Just one click and the automatic igniter ignites the fuel fed to the burner. The automatic igniter combined with the RTC clock allows you to program the entire working week of the device. The device operation timer can be set separately for SUMMER and WINTER modes.

The screw feeder precisely doses the fuel, is resistant to abrasion, corrosion and high temperature.

Prevents damage to the gear motor. When there is an element in the feeder that the screw will not be able to push out, the cotter pin will break, which will protect the boiler against more serious damage to the feeding system.

Boiler technical data

| PARAMETERS | S.I. UNIT | SMART EKO PLUS 15 |

| Nominal heat output | [kW] | 15 |

| Boiler power range | [kW] | 4,5-15 |

| Area that can be heated* | [m2] | 67,5-225 |

| Water capacity | [L] | 48 |

| Maximum working pressure | [bar] | 3 |

| Maximum operating temperature | [°C] | 80 |

| Test pressure | [bar] | 4,5 |

| Fuel tank capacity | [L] | 200 |

| Fuel tank capacity | [kg] | 146 |

| Fuel | [-] | eco-pea coal Φ0-32mm |

| Electrical connection | [-] | 5A; ~230V; 50Hz |

| Electric power consumption | [W] | 350 |

| Temperature controller setting range | [°C] | 60-80 (every 1°C) |

| Chimney draft required | [Pa] | 16 |

| Boiler weight | [kg] | 380 |

*A new building with very good thermal insulation was used for the calculations.

| PARAMETERS | S.I. UNIT | SMART EKO PLUS 20 |

| Nominal heat output | [kW] | 20 |

| Boiler power range | [kW] | 6-20 |

| Area that can be heated* | [m2] | 90-300 |

| Water capacity | [L] | 60 |

| Maximum working pressure | [bar] | 3 |

| Maximum operating temperature | [°C] | 80 |

| Test pressure | [bar] | 4,5 |

| Fuel tank capacity | [L] | 200 |

| Fuel tank capacity | [kg] | 146 |

| Fuel | [-] | eco-pea coal Φ0-32mm |

| Electrical connection | [-] | 5A; ~230V; 50Hz |

| Electric power consumption | [W] | 350 |

| Temperature controller setting range | [°C] | 60-80 (every 1°C) |

| Chimney draft required | [Pa] | 20 |

| Boiler weight | [kg] | 405 |

*A new building with very good thermal insulation was used for the calculations.

| PARAMETERS | S.I. UNIT | SMART EKO PLUS 25 |

| Nominal heat output | [kW] | 25 |

| Boiler power range | [kW] | 7,5-25 |

| Area that can be heated* | [m2] | 112,5-375 |

| water capacity | [L] | 71 |

| Maximum working pressure | [bar] | 3 |

| Maximum operating temperature | [°C] | 80 |

| Test pressure | [bar] | 4,5 |

| Fuel tank capacity | [L] | 200 |

| Fuel tank capacity | [kg] | 146 |

| Fuel | [-] | eco-pea coal Φ0-32mm |

| Electrical connection | [-] | 5A; ~230V; 50Hz |

| Electric power consumption | [W] | 350 |

| Temperature controller setting range | [°C] | 60-80 (every 1°C) |

| Chimney draft required | [Pa] | 21 |

| Boiler weight | [kg] | 480 |

*A new building with very good thermal insulation was used for the calculations.

Certificates, class, boiler emissivity

| PARAMETERS | S.I. UNIT | SMART EKO PLUS 15 |

| Ecodesign (Eco Design) | [-] | Yes |

| Boiler class | [-] | 5 |

| Energy class | [-] | B |

| Seasonal emissivity of particulate matter | [mg/m3] | 23,35 |

| Efficiency for nominal power | [%] | 90,69 |

| Particulate nominal emissivity | [mg/m3] | 28,02 |

| Efficiency for minimum power | [%] | 90,95 |

| Minimum emissivity of particulates | [mg/m3] | 22,52 |

| PARAMETERS | S.I. UNIT | SMART EKO PLUS 20 |

| Ecodesign (Eco Design) | [-] | Yes |

| Boiler class | [-] | 5 |

| Energy class | [-] | B |

| Seasonal emissivity of particulate matter | [mg/m3] | 22,58 |

| Efficiency for nominal power | [%] | 91,0 |

| Particulate nominal emissivity | [mg/m3] | 30,06 |

| Efficiency for minimum power | [%] | 90,71 |

| Minimum emissivity of particulates | [mg/m3] | 21,26 |

| PARAMETERS | S.I. UNIT | SMART EKO PLUS 25 |

| Ecodesign (Eco Design) | [-] | Yes |

| Boiler class | [-] | 5 |

| Energy class | [-] | B |

| Seasonal emissivity of particulate matter | [mg/m3] | 23,19 |

| Efficiency for nominal power | [%] | 90,94 |

| Particulate nominal emissivity | [mg/m3] | 28,90 |

| Efficiency for minimum power | [%] | 90,72 |

| Minimum emissivity of particulates | [mg/m3] | 22,18 |

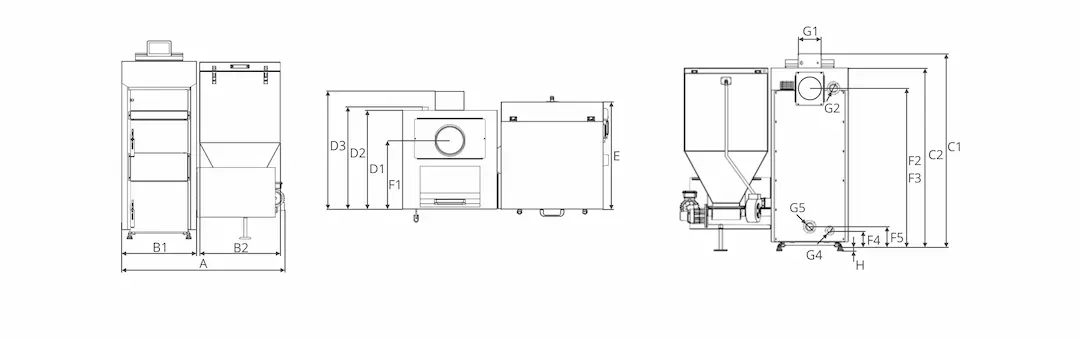

Boiler dimensions

| DIMENSION | S.I. UNIT | SMART EKO PLUS 15 |

| A | [mm] | 1135 |

| B1 | [mm] | 535 |

| B2 | [mm] | 580 |

| C1 | [mm] | 1340 |

| C2 | [mm] | 1240 |

| D1 | [mm] | 560 |

| D2 | [mm] | 590 |

| D3 | [mm] | 680 |

| E | [mm] | 610 |

| F1 | [mm] | 435 |

| F2 | [mm] | 1100 |

| F3 | [mm] | 1100 |

| F4 | [mm] | 115 |

| F5 | [mm] | 140 |

| G1 | [mm] | 160 |

| G2 | [cal] | 1 1/2 |

| G4 | [cal] | 3/4 |

| G5 | [cal] | 1 1/2 |

| H | [mm] | 30 |

| DIMENSION | S.I. UNIT | SMART EKO PLUS 20 |

| A | [mm] | 1135 |

| B1 | [mm] | 535 |

| B2 | [mm] | 580 |

| C1 | [mm] | 1400 |

| C2 | [mm] | 1300 |

| D1 | [mm] | 630 |

| D2 | [mm] | 660 |

| D3 | [mm] | 760 |

| E | [mm] | 630 |

| F1 | [mm] | 505 |

| F2 | [mm] | 1155 |

| F3 | [mm] | 1155 |

| F4 | [mm] | 115 |

| F5 | [mm] | 140 |

| G1 | [mm] | 160 |

| G2 | [cal] | 1 1/2 |

| G4 | [cal] | 3/4 |

| G5 | [cal] | 1 1/2 |

| H | [mm] | 30 |

| DIMENSION | S.I. UNIT | SMART EKO PLUS 25 |

| A | [mm] | 1185 |

| B1 | [mm] | 585 |

| B2 | [mm] | 580 |

| C1 | [mm] | 1400 |

| C2 | [mm] | 1300 |

| D1 | [mm] | 720 |

| D2 | [mm] | 750 |

| D3 | [mm] | 845 |

| E | [mm] | 630 |

| F1 | [mm] | 595 |

| F2 | [mm] | 1155 |

| F3 | [mm] | 1155 |

| F4 | [mm] | 115 |

| F5 | [mm] | 140 |

| G1 | [mm] | 160 |

| G2 | [cal] | 1 1/2 |

| G4 | [cal] | 3/4 |

| G5 | [cal] | 1 1/2 |

| H | [mm] | 30 |

Boiler documentation

DTR manual

| Technical and operational documentation for the SMART EKO PLUS boiler | Download |

Driver Manual

| PLATINUM driver manual | Download |

EcoDesign certificate

| Boiler compliant with the requirements of the EcoDesign standard (EcoDesign) | Download |

Energy label

| Energy class A+ | Download |

Product fiche in accordance with EU Regulation 2015/1187

| In accordance with EU Regulation 2015/1187 supplementing Directive 2009/125/EC of the European Parliament and of the Council | Download |

Product sheet according to EU Regulation 2015/1189

| Compliant with the Regulation of the EU Commission 2015/1189 of April 28, 2015. | Download |

Foreign sales

Paweł Czepiel

Export manager

Language: Russian, English

Monday-Friday (7:00 a.m. – 3:00 p.m.)

Phone:

+48 663 45 32 22

+48 85 711 94 54 ext. 17

E-mail:

p.czepiel@metalfach.com.pl

Dane adresowe:

METAL-FACH Technika Grzewcza

Sp. z o.o.

- ul. Sikorskiego 66, 16-100 Sokółka, Polska

- NIP: 545-182-60-12

- REGON: 523566030

Kontakt ogólny:

Otwarte:

- Pon.-Pt. 07: 00-15:00

- Tel. +48 85 711 94 54

- E-mail: sprzedaz@metalfach.com.pl

Kontakt serwis:

- Pon.-Pt. 7:00-20:00

- Sob. 8:00-14:00

- Niedz. 10:00-14:00

- Tel. +48 85 711 94 56

- E-mail: serwis.kotly@metalfach.com.pl

Kontakt serwis:

Pompy ciepła:

- Pon.-Pt. 7:00-15:00

- Tel. +48 85 711 94 54 wew. 12

- E-mail: serwis.pompy@metalfach.com.pl

Dofinansowanie:

Social Media:

2010-2024 © Copyright METAL-FACH Technika Grzewcza Sp. z o.o. | Wszelkie prawa zastrzeżone.